- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Deep drawing |

5 | Tolerance | +/-0.2mm |

6 | Surface treatment | Powder coating, galvanization, anodizing |

7 | Application | Industry |

8 | Warranty time | 1 -2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

▼ Product Display

Metalli's deep drawing capabilities

● Product dimension up to Length*Width 1200*1000 mm

● Depth or height up to 500 mm

● Wall thickness up to 6 mm

● Tolerance ±0.2 mm or less

● Common shapes covering round, cone, square, rectangle, and irregular

● Tools design available in house

● 10 hydraulic press machines from 100 tons to 1000 tons

Brief of deep drawing

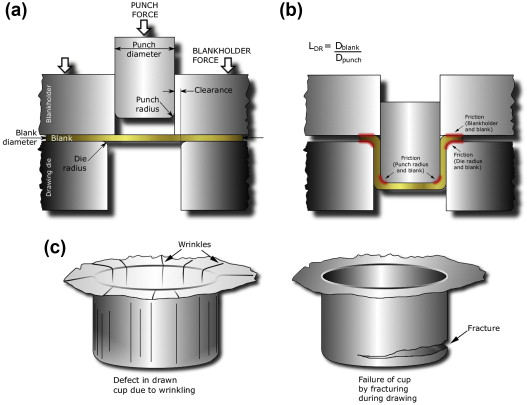

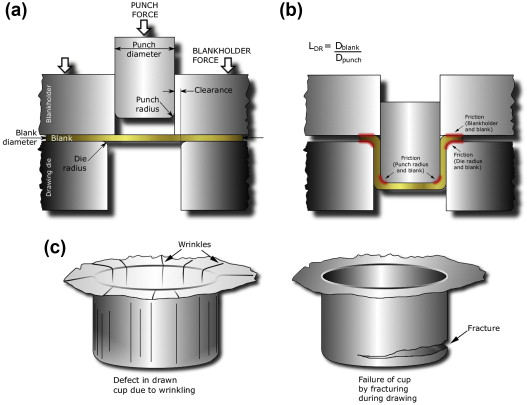

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Deep drawing |

5 | Tolerance | +/-0.2mm |

6 | Surface treatment | Powder coating, galvanization, anodizing |

7 | Application | Industry |

8 | Warranty time | 1 -2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

▼ Product Display

Metalli's deep drawing capabilities

● Product dimension up to Length*Width 1200*1000 mm

● Depth or height up to 500 mm

● Wall thickness up to 6 mm

● Tolerance ±0.2 mm or less

● Common shapes covering round, cone, square, rectangle, and irregular

● Tools design available in house

● 10 hydraulic press machines from 100 tons to 1000 tons

Brief of deep drawing

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.