- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Deep drawing |

5 | Tolerance | +/-0.2mm |

6 | Surface treatment | Powder coating, galvanization, anodizing |

7 | Application | Industry |

8 | Warranty time | 1 -2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

▼ Product Display

Metalli's expertise in deep drawing

● Able to produce products with dimensions of up to 1200mm in length and 1000mm in width

● Capable of achieving depths or heights of up to 500mm

● Able to accommodate wall thicknesses of up to 6mm

● Maintains a tolerance of ±0.2mm or less

● Offers a wide range of common shapes including round, cone, square, rectangle, and irregular

● Provides in-house tool design services

● Utilizes 10 hydraulic press machines ranging from 100 to 1000 tons of force.

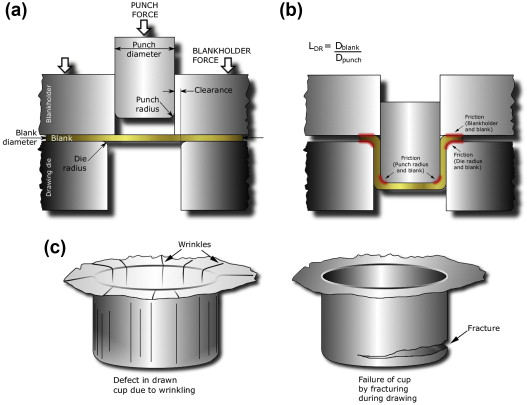

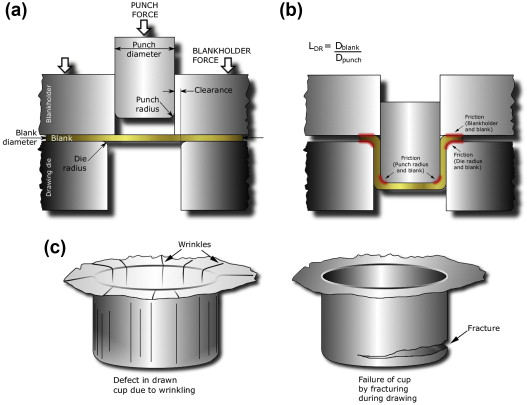

Brief of deep drawing

Deep Drawing is an important sheet metal forming process that appears in many industries. Like other sheet metal forming processes, deep drawing is characterized by very complicated deformation affected by the process parameters which include die and punch shapes, blank shape, the blank holding force, material properties and lubrication. Due to the complex functions that describe the process output as related to these parameters, the optimization in the deep drawing process is a challenging task. Recently, there has been a growing interest in the research community to apply optimization techniques to this process. In this paper we present a comprehensive

review on the optimization techniques used and identify directions for future research.

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Deep drawing |

5 | Tolerance | +/-0.2mm |

6 | Surface treatment | Powder coating, galvanization, anodizing |

7 | Application | Industry |

8 | Warranty time | 1 -2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

▼ Product Display

Metalli's expertise in deep drawing

● Able to produce products with dimensions of up to 1200mm in length and 1000mm in width

● Capable of achieving depths or heights of up to 500mm

● Able to accommodate wall thicknesses of up to 6mm

● Maintains a tolerance of ±0.2mm or less

● Offers a wide range of common shapes including round, cone, square, rectangle, and irregular

● Provides in-house tool design services

● Utilizes 10 hydraulic press machines ranging from 100 to 1000 tons of force.

Brief of deep drawing

Deep Drawing is an important sheet metal forming process that appears in many industries. Like other sheet metal forming processes, deep drawing is characterized by very complicated deformation affected by the process parameters which include die and punch shapes, blank shape, the blank holding force, material properties and lubrication. Due to the complex functions that describe the process output as related to these parameters, the optimization in the deep drawing process is a challenging task. Recently, there has been a growing interest in the research community to apply optimization techniques to this process. In this paper we present a comprehensive

review on the optimization techniques used and identify directions for future research.