- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum, brass,etc |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Stamping |

5 | Tolerance | +/-0.1mm |

6 | Surface treatment | Powder coating, galvanization, anodizing, etc |

7 | Application | Industry |

8 | Warranty time | 1-2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

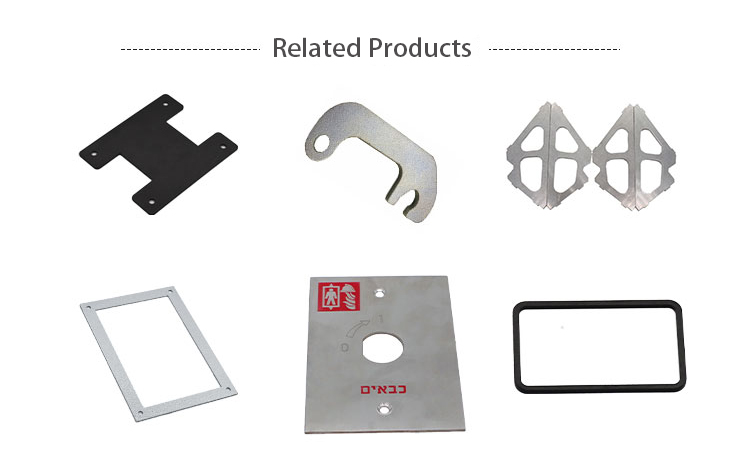

Product Details

Working Principle

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It is a complex process that can include a number of metal forming techniques - blanking, punching, bending and piercing

Metalli's stamping capability

● Can accommodate products with dimensions of up to 1200mm in length and 600mm in width.

● Capable of handling wall thicknesses up to 12mm.

● Maintains a tolerance level of ±0.1mm or less.

● Designs and manufactures tools in-house.

● Offers multi-step tool design and manufacturing to achieve high-speed mass production at the lowest unit price.

More Fabrication Options

Applications:

1. Automotive industry: Metal stamping is widely used in the automotive industry to produce parts and components such as body panels, engine components, and suspension parts.

2. Aerospace industry: This process is used to produce parts and components for aircraft such as wing panels, engine components, and landing gear parts.

3. Electronics industry: Metal stamping is used to produce parts for electronic devices such as computer components, mobile phones, and home appliances.

4. Construction industry: This process is used to produce parts and components for construction equipment, such as excavators, bulldozers, and cranes.

Surface Treatment

Safe Package Before Shipping

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum, brass,etc |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Stamping |

5 | Tolerance | +/-0.1mm |

6 | Surface treatment | Powder coating, galvanization, anodizing, etc |

7 | Application | Industry |

8 | Warranty time | 1-2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

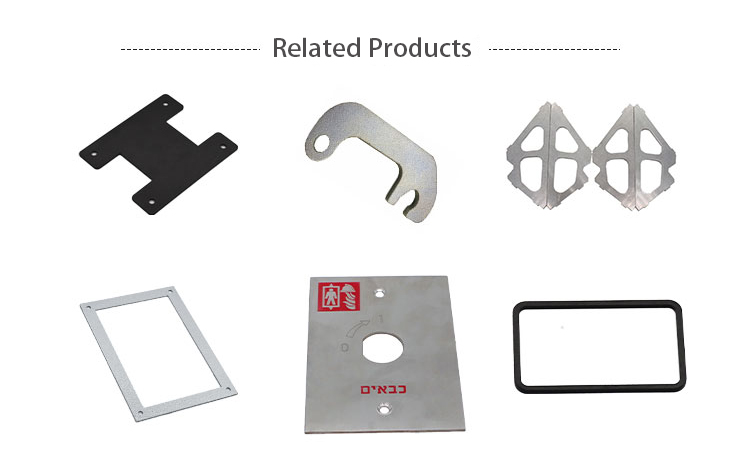

Product Details

Working Principle

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It is a complex process that can include a number of metal forming techniques - blanking, punching, bending and piercing

Metalli's stamping capability

● Can accommodate products with dimensions of up to 1200mm in length and 600mm in width.

● Capable of handling wall thicknesses up to 12mm.

● Maintains a tolerance level of ±0.1mm or less.

● Designs and manufactures tools in-house.

● Offers multi-step tool design and manufacturing to achieve high-speed mass production at the lowest unit price.

More Fabrication Options

Applications:

1. Automotive industry: Metal stamping is widely used in the automotive industry to produce parts and components such as body panels, engine components, and suspension parts.

2. Aerospace industry: This process is used to produce parts and components for aircraft such as wing panels, engine components, and landing gear parts.

3. Electronics industry: Metal stamping is used to produce parts for electronic devices such as computer components, mobile phones, and home appliances.

4. Construction industry: This process is used to produce parts and components for construction equipment, such as excavators, bulldozers, and cranes.

Surface Treatment

Safe Package Before Shipping