- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Deep drawing |

5 | Tolerance | +/-0.2mm |

6 | Surface treatment | Powder coating, galvanization, anodizing |

7 | Application | Industry |

8 | Warranty time | 1 -2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

▼ Product Display

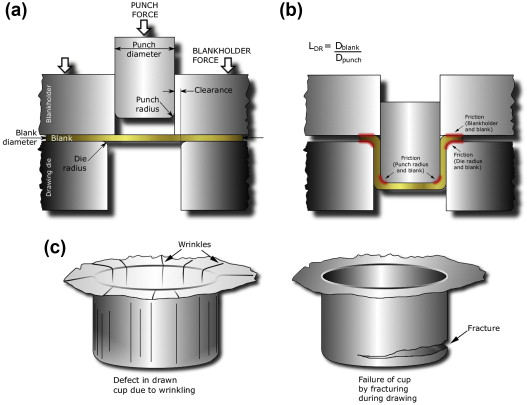

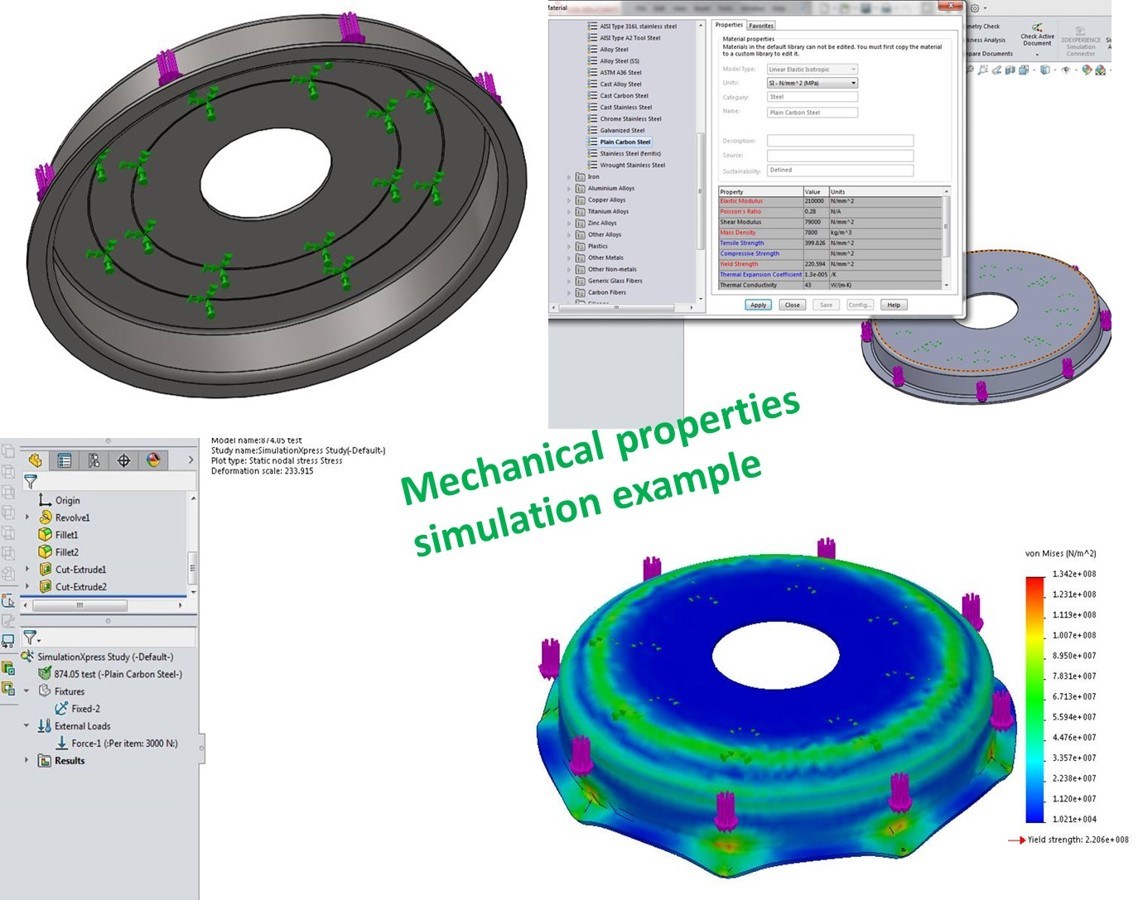

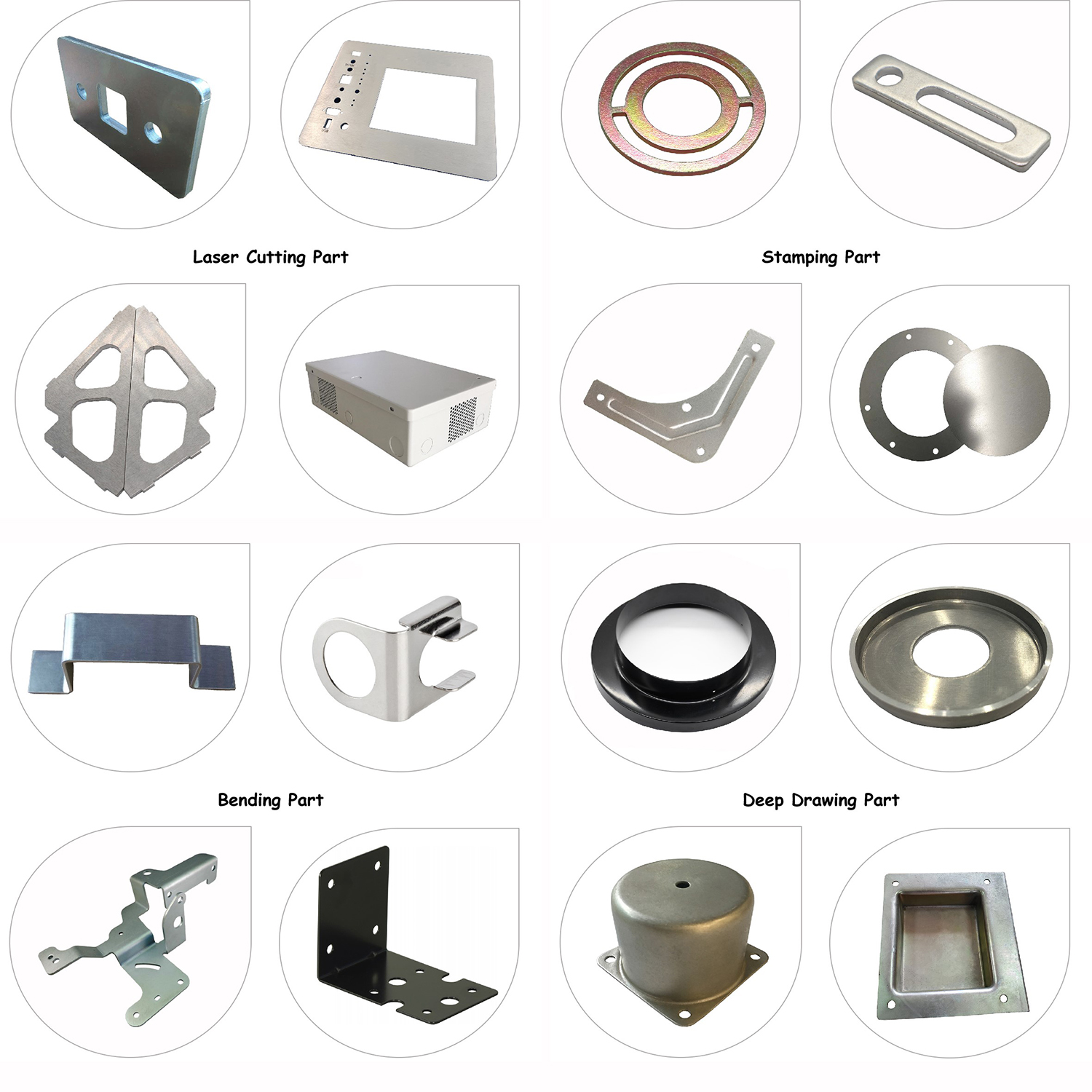

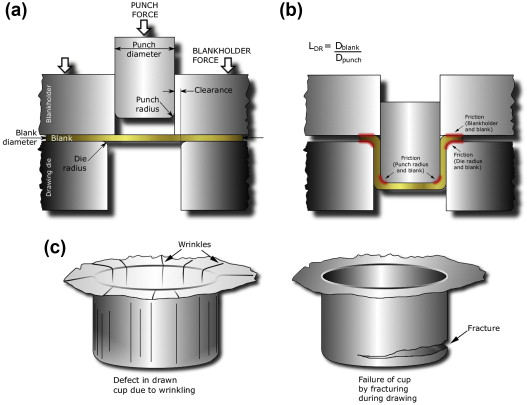

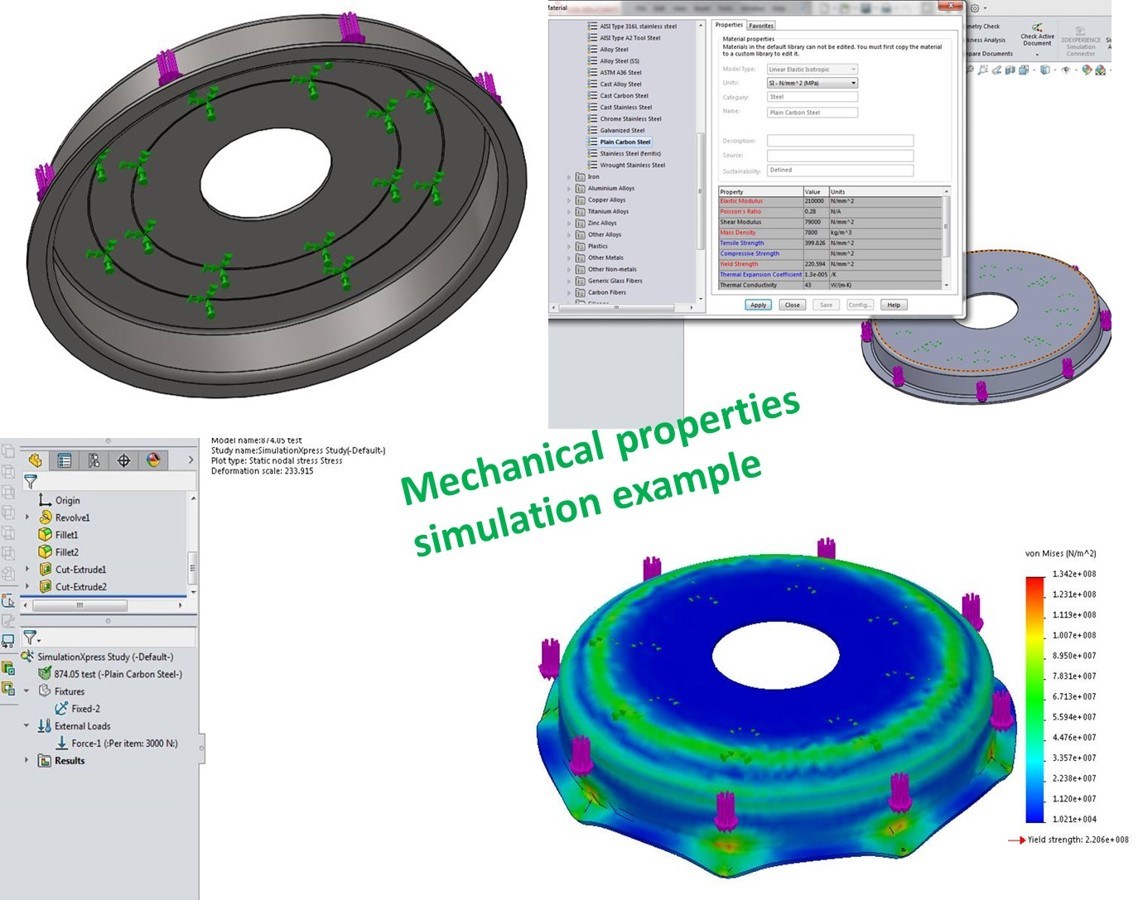

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

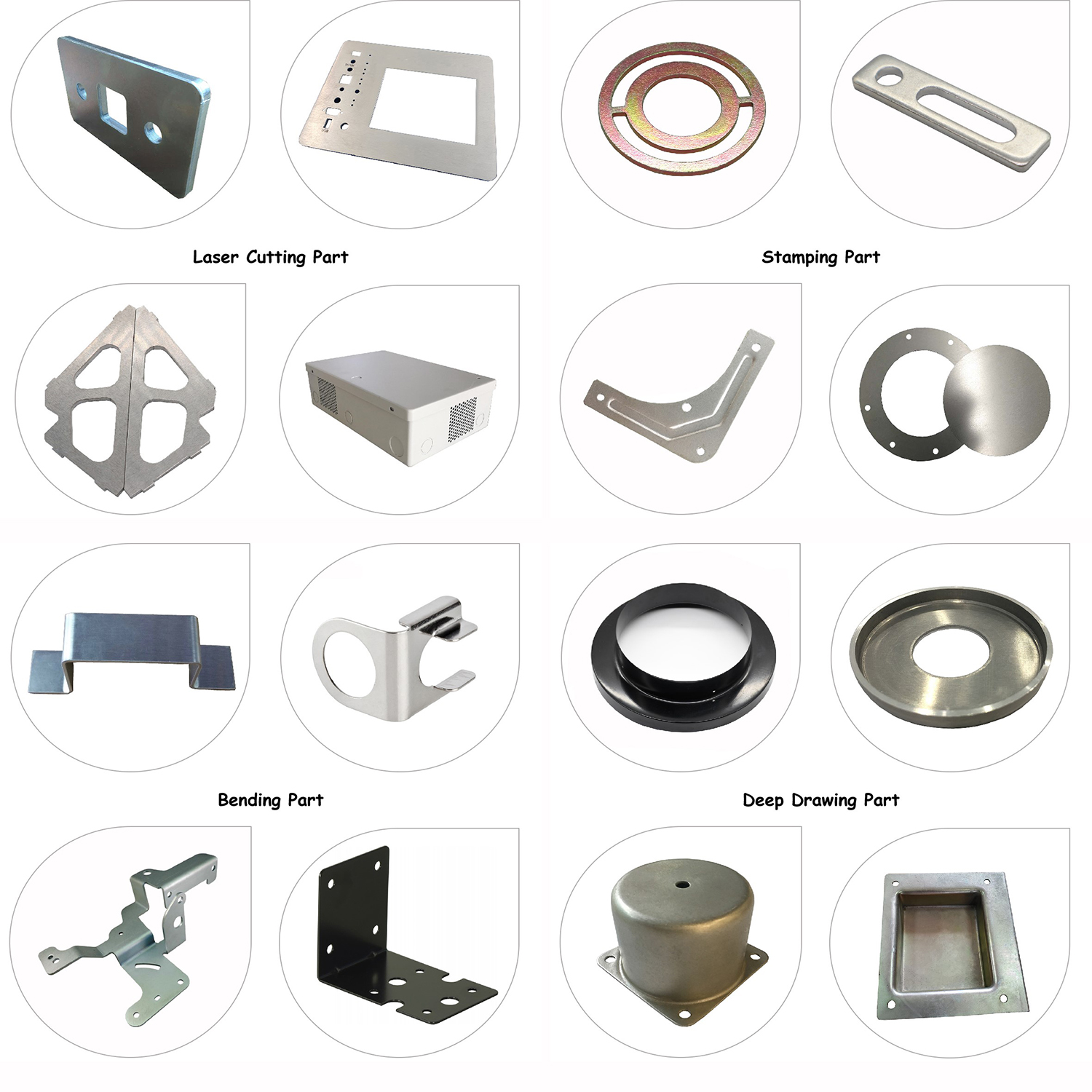

Our deep drawing parts are made from high-quality materials like mild steel, stainless steel, and aluminum, ensuring they are strong and durable. Whether you need parts for industrial machines, car components, or any other use, our materials are suitable for different industries and environments.

The manufacturing process of these parts involves deep drawing, which ensures precise and consistent results. This method allows us to create intricate shapes and designs that meet your specific needs. With our deep drawing expertise, you can trust that our fabricated parts are precise and functional.

To further enhance the longevity and aesthetics of our deep drawing parts, we offer a range of surface treatments. Choose from powder coating, galvanization, or anodizing to provide an added layer of protection against corrosion, wear, and tear. These surface treatments not only enhance the visual appeal of the parts but also ensure their longevity in demanding environments.

Metalli possesses extensive deep drawing capabilities, allowing for the production of products with dimensions up to 1200 mm in length and 1000 mm in width. Additionally, products can have a depth or height of up to 500 mm and a wall thickness of up to 6 mm. Our manufacturing process adheres to a strict tolerance of ±0.2 mm or less. We are able to create a wide range of shapes, including round, cone, square, rectangle, and irregular shapes. Our in-house team is skilled in tool design, ensuring efficient and precise production. With a fleet of 10 hydraulic press machines ranging from 100 tons to 1000 tons, we have the capacity to handle various project sizes.

More Options

Safe & Careful Package

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Deep drawing |

5 | Tolerance | +/-0.2mm |

6 | Surface treatment | Powder coating, galvanization, anodizing |

7 | Application | Industry |

8 | Warranty time | 1 -2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

▼ Product Display

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

Our deep drawing parts are made from high-quality materials like mild steel, stainless steel, and aluminum, ensuring they are strong and durable. Whether you need parts for industrial machines, car components, or any other use, our materials are suitable for different industries and environments.

The manufacturing process of these parts involves deep drawing, which ensures precise and consistent results. This method allows us to create intricate shapes and designs that meet your specific needs. With our deep drawing expertise, you can trust that our fabricated parts are precise and functional.

To further enhance the longevity and aesthetics of our deep drawing parts, we offer a range of surface treatments. Choose from powder coating, galvanization, or anodizing to provide an added layer of protection against corrosion, wear, and tear. These surface treatments not only enhance the visual appeal of the parts but also ensure their longevity in demanding environments.

Metalli possesses extensive deep drawing capabilities, allowing for the production of products with dimensions up to 1200 mm in length and 1000 mm in width. Additionally, products can have a depth or height of up to 500 mm and a wall thickness of up to 6 mm. Our manufacturing process adheres to a strict tolerance of ±0.2 mm or less. We are able to create a wide range of shapes, including round, cone, square, rectangle, and irregular shapes. Our in-house team is skilled in tool design, ensuring efficient and precise production. With a fleet of 10 hydraulic press machines ranging from 100 tons to 1000 tons, we have the capacity to handle various project sizes.

More Options

Safe & Careful Package