- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

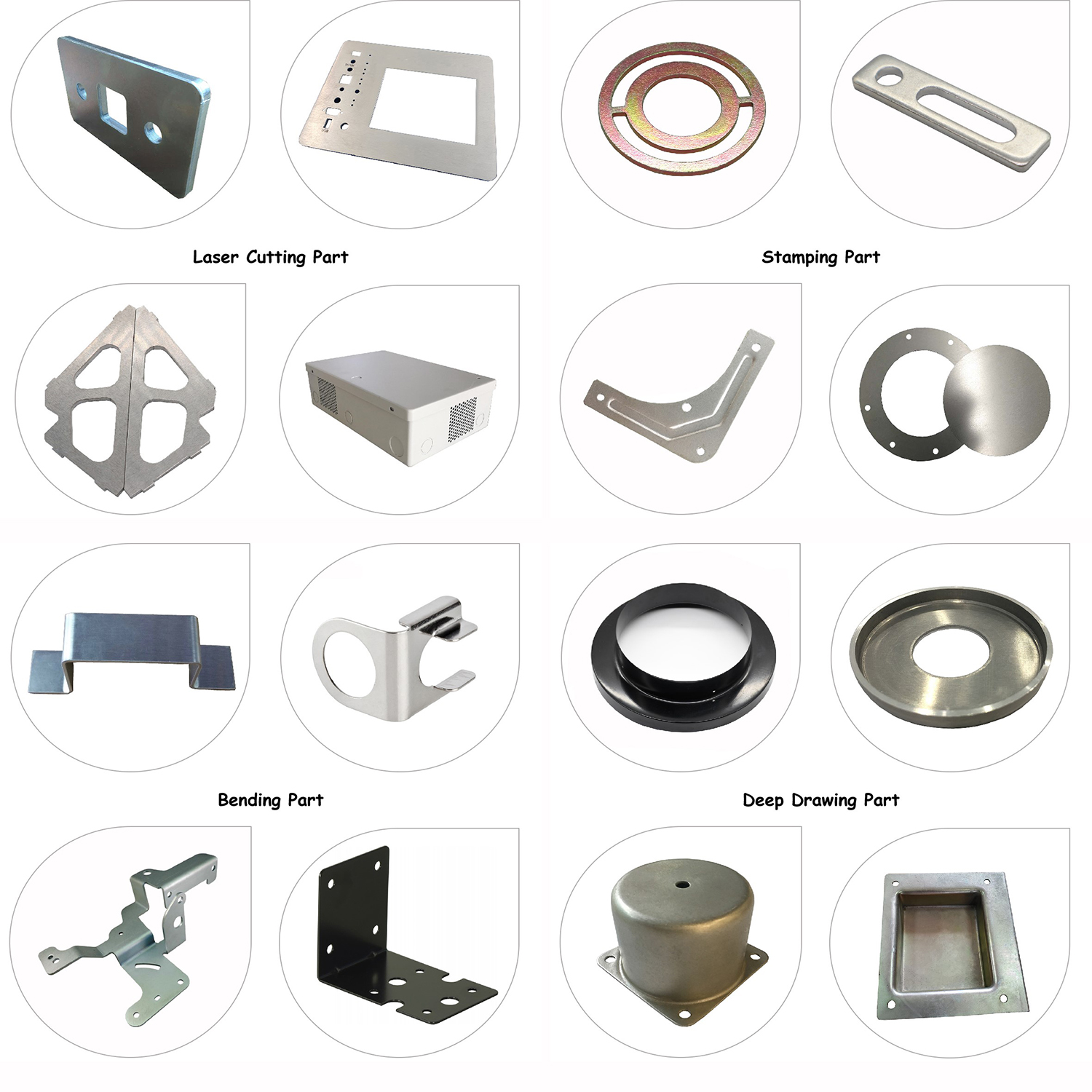

Custom Metal Fabrication Deep Drawn Parts are specialized components that are manufactured through a process called deep drawing. This process involves the use of metal sheets that are formed into complex shapes and designs using a combination of pressure and dies. These deep drawn parts are widely used in various industries, including automotive, aerospace, electronics, and more.

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Deep drawing |

5 | Tolerance | +/-0.2mm |

6 | Surface treatment | Powder coating, galvanization, anodizing |

7 | Application | Industry |

8 | Warranty time | 1 -2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

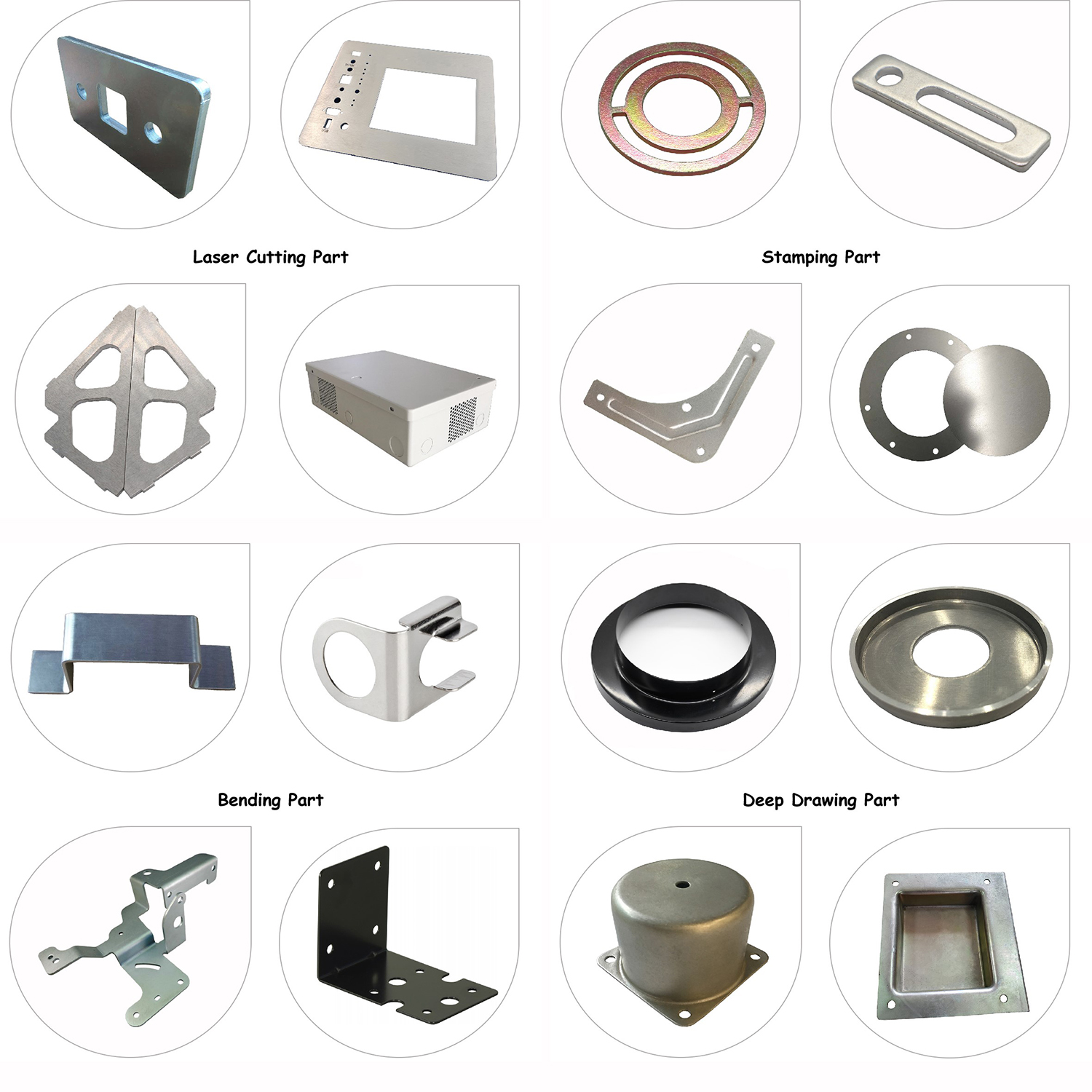

▼ Product Display

Metalli's deep drawing capabilities

● Product dimension up to Length*Width 1200*1000 mm

● Depth or height up to 500 mm

● Wall thickness up to 6 mm

● Tolerance ±0.2 mm or less

● Common shapes covering round, cone, square, rectangle, and irregular

● Tools design available in house

● 10 hydraulic press machines from 100 tons to 1000 tons

Brief of deep drawing

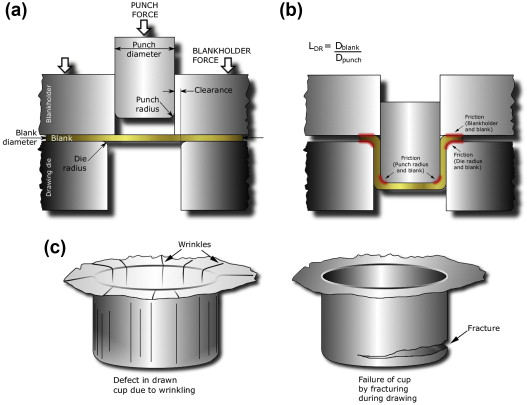

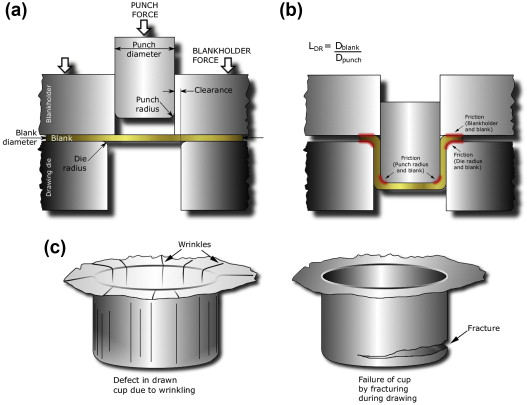

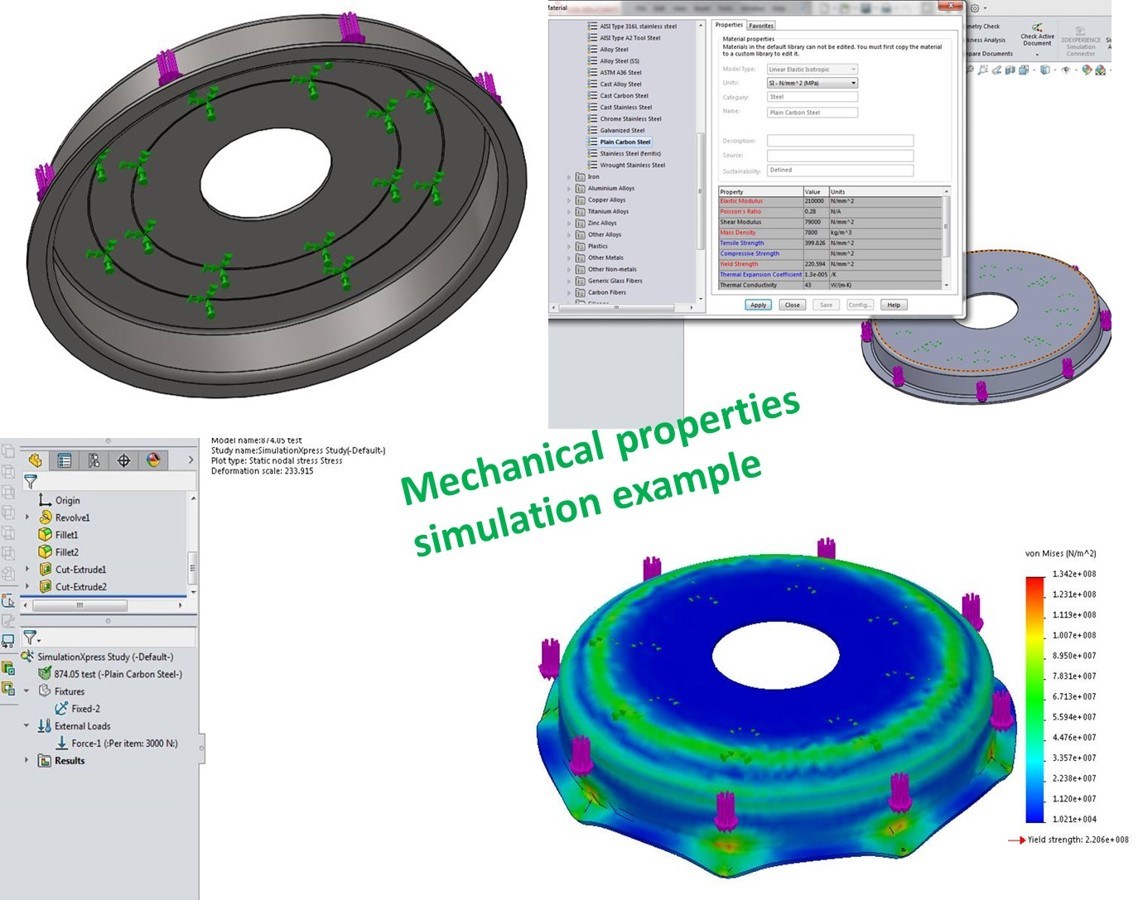

Deep drawing is a method used to shape sheet metal by pulling it into a die with a punch. This process allows the material to retain its original form while transforming into a new shape. When the depth of the drawn part is greater than its diameter, it is considered a "deep" drawing. To achieve this, the part is redrawn through a series of dies. The area of the sheet metal in the die shoulder, known as the flange region, experiences both radial drawing stress and tangential compressive stress due to the material retention. These compressive stresses, also known as hoop stresses, can cause wrinkles in the flange (known as wrinkles of the first order). To prevent these wrinkles, a blank holder is used. The purpose of the blank holder is to control the flow of material into the die radius.

Made with high-quality materials like mild steel, stainless steel, and aluminum, our deep drawing components are incredibly strong and durable. Whether you need parts for machines, cars, or anything else, our selection of materials ensures they will work well in different industries and environments.

The deep drawing method we use to make these parts ensures they are extremely precise and consistent. This technique allows us to create intricate shapes and designs, so we can meet your specific needs. With our deep drawing expertise, you can trust that our fabricated parts will be accurate and work perfectly.

In order to improve the durability and appearance of our deep drawing components, we provide a variety of surface treatments. You can select from powder coating, galvanization, or anodizing to give an extra shield against rust, deterioration, and damage. These surface treatments not only enhance the visual attractiveness of the components but also guarantee their long lifespan in challenging conditions.

Metalli's deep drawing capabilities

● Product dimension up to Length*Width 1200*1000 mm

● Depth or height up to 500 mm

● Wall thickness up to 6 mm

● Tolerance ±0.2 mm or less

● Common shapes covering round, cone, square, rectangle, and irregular

● Tools design available in house

● 10 hydraulic press machines from 100 tons to 1000 tons

More Options

Safe & Careful Package

Custom Metal Fabrication Deep Drawn Parts are specialized components that are manufactured through a process called deep drawing. This process involves the use of metal sheets that are formed into complex shapes and designs using a combination of pressure and dies. These deep drawn parts are widely used in various industries, including automotive, aerospace, electronics, and more.

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Deep drawing |

5 | Tolerance | +/-0.2mm |

6 | Surface treatment | Powder coating, galvanization, anodizing |

7 | Application | Industry |

8 | Warranty time | 1 -2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

▼ Product Display

Metalli's deep drawing capabilities

● Product dimension up to Length*Width 1200*1000 mm

● Depth or height up to 500 mm

● Wall thickness up to 6 mm

● Tolerance ±0.2 mm or less

● Common shapes covering round, cone, square, rectangle, and irregular

● Tools design available in house

● 10 hydraulic press machines from 100 tons to 1000 tons

Brief of deep drawing

Deep drawing is a method used to shape sheet metal by pulling it into a die with a punch. This process allows the material to retain its original form while transforming into a new shape. When the depth of the drawn part is greater than its diameter, it is considered a "deep" drawing. To achieve this, the part is redrawn through a series of dies. The area of the sheet metal in the die shoulder, known as the flange region, experiences both radial drawing stress and tangential compressive stress due to the material retention. These compressive stresses, also known as hoop stresses, can cause wrinkles in the flange (known as wrinkles of the first order). To prevent these wrinkles, a blank holder is used. The purpose of the blank holder is to control the flow of material into the die radius.

Made with high-quality materials like mild steel, stainless steel, and aluminum, our deep drawing components are incredibly strong and durable. Whether you need parts for machines, cars, or anything else, our selection of materials ensures they will work well in different industries and environments.

The deep drawing method we use to make these parts ensures they are extremely precise and consistent. This technique allows us to create intricate shapes and designs, so we can meet your specific needs. With our deep drawing expertise, you can trust that our fabricated parts will be accurate and work perfectly.

In order to improve the durability and appearance of our deep drawing components, we provide a variety of surface treatments. You can select from powder coating, galvanization, or anodizing to give an extra shield against rust, deterioration, and damage. These surface treatments not only enhance the visual attractiveness of the components but also guarantee their long lifespan in challenging conditions.

Metalli's deep drawing capabilities

● Product dimension up to Length*Width 1200*1000 mm

● Depth or height up to 500 mm

● Wall thickness up to 6 mm

● Tolerance ±0.2 mm or less

● Common shapes covering round, cone, square, rectangle, and irregular

● Tools design available in house

● 10 hydraulic press machines from 100 tons to 1000 tons

More Options

Safe & Careful Package