- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Deep drawing |

5 | Tolerance | +/-0.2mm |

6 | Surface treatment | Powder coating, galvanization, anodizing |

7 | Application | Industry |

8 | Warranty time | 1 -2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

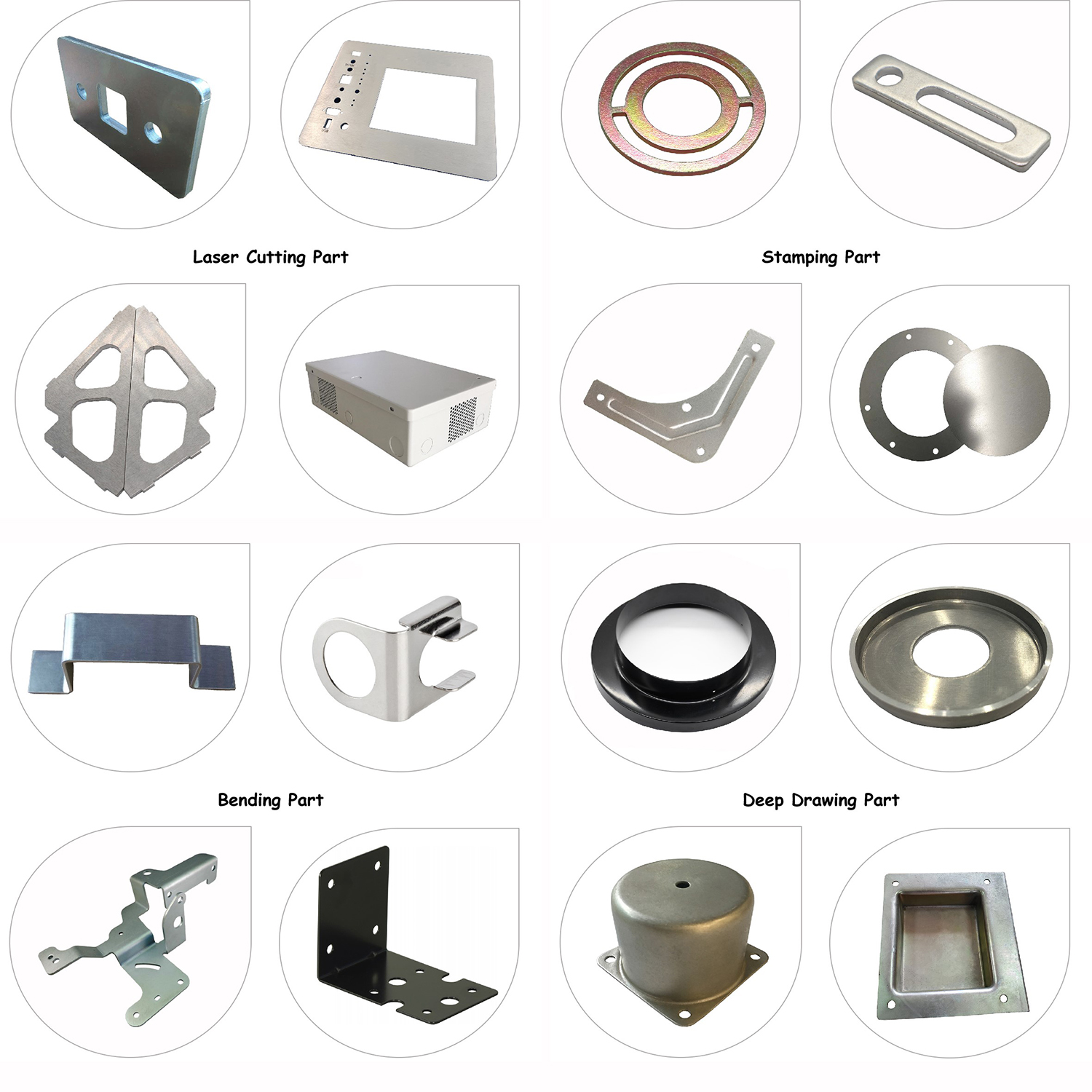

▼ Product Display

Brief of deep drawing

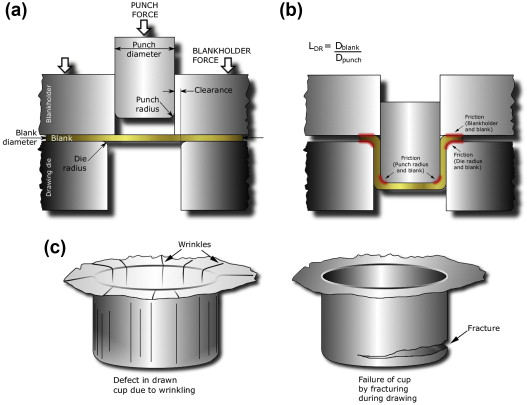

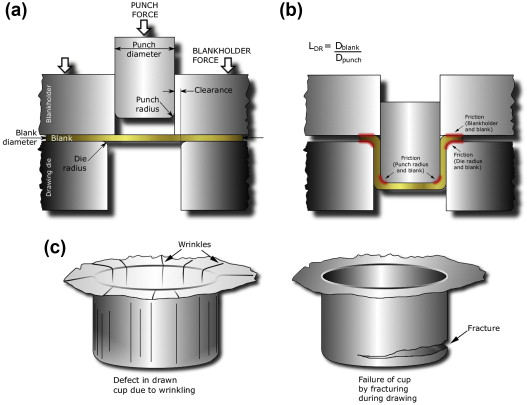

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

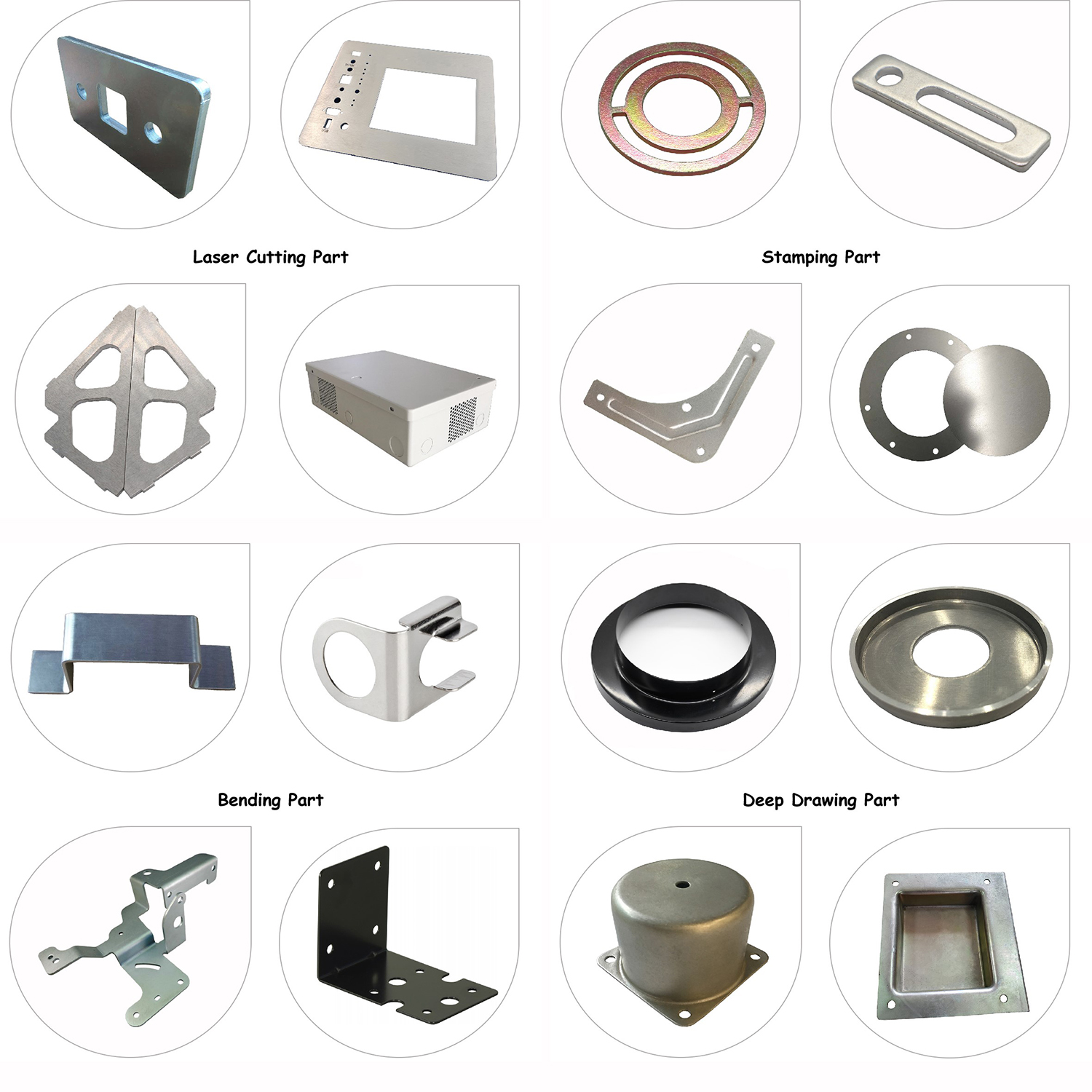

Constructed from premium materials such as mild steel, stainless steel, and aluminum, our deep drawing parts offer exceptional strength and resilience. Whether you require parts for industrial machinery, automotive components, or any other application, our range of materials ensures compatibility with various industries and environments.

The deep drawing process employed in the manufacturing of these parts guarantees superior accuracy and consistency. This technique allows for the creation of complex shapes and geometries, enabling us to cater to your specific design requirements. With our expertise in deep drawing, you can be confident in the precision and functionality of our fabricated parts.

To further enhance the longevity and aesthetics of our deep drawing parts, we offer a range of surface treatments. Choose from powder coating, galvanization, or anodizing to provide an added layer of protection against corrosion, wear, and tear. These surface treatments not only enhance the visual appeal of the parts but also ensure their longevity in demanding environments.

Metalli's deep drawing capabilities

● Product dimension up to Length*Width 1200*1000 mm

● Depth or height up to 500 mm

● Wall thickness up to 6 mm

● Tolerance ±0.2 mm or less

● Common shapes covering round, cone, square, rectangle, and irregular

● Tools design available in house

● 10 hydraulic press machines from 100 tons to 1000 tons

More Options

Safe & Careful Package

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Deep drawing |

5 | Tolerance | +/-0.2mm |

6 | Surface treatment | Powder coating, galvanization, anodizing |

7 | Application | Industry |

8 | Warranty time | 1 -2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

▼ Product Display

Brief of deep drawing

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

Constructed from premium materials such as mild steel, stainless steel, and aluminum, our deep drawing parts offer exceptional strength and resilience. Whether you require parts for industrial machinery, automotive components, or any other application, our range of materials ensures compatibility with various industries and environments.

The deep drawing process employed in the manufacturing of these parts guarantees superior accuracy and consistency. This technique allows for the creation of complex shapes and geometries, enabling us to cater to your specific design requirements. With our expertise in deep drawing, you can be confident in the precision and functionality of our fabricated parts.

To further enhance the longevity and aesthetics of our deep drawing parts, we offer a range of surface treatments. Choose from powder coating, galvanization, or anodizing to provide an added layer of protection against corrosion, wear, and tear. These surface treatments not only enhance the visual appeal of the parts but also ensure their longevity in demanding environments.

Metalli's deep drawing capabilities

● Product dimension up to Length*Width 1200*1000 mm

● Depth or height up to 500 mm

● Wall thickness up to 6 mm

● Tolerance ±0.2 mm or less

● Common shapes covering round, cone, square, rectangle, and irregular

● Tools design available in house

● 10 hydraulic press machines from 100 tons to 1000 tons

More Options

Safe & Careful Package