- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum, brass,etc |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Stamping |

5 | Tolerance | +/-0.1mm |

6 | Surface treatment | Powder coating, galvanization, anodizing, etc |

7 | Application | Industry |

8 | Warranty time | 1-2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

Metal stamping is a manufacturing process that involves shaping and cutting metal sheets into desired shapes and sizes using a stamping press machine. The metal sheets are fed into the machine, where they are subjected to high pressure, which causes the metal to take the shape of the die.

Metal stamping is a precise and cost-effective manufacturing process that can create a wide range of products. It plays a crucial role in the manufacturing industry due to its versatility and various techniques employed. Typically, stamping is performed on cold metal sheets, while hot metal forming operations can be done through forging.

Features of Metal Stamping:

Precision: Metal stamping is a highly precise manufacturing process that can produce complex shapes and designs with accuracy and consistency.

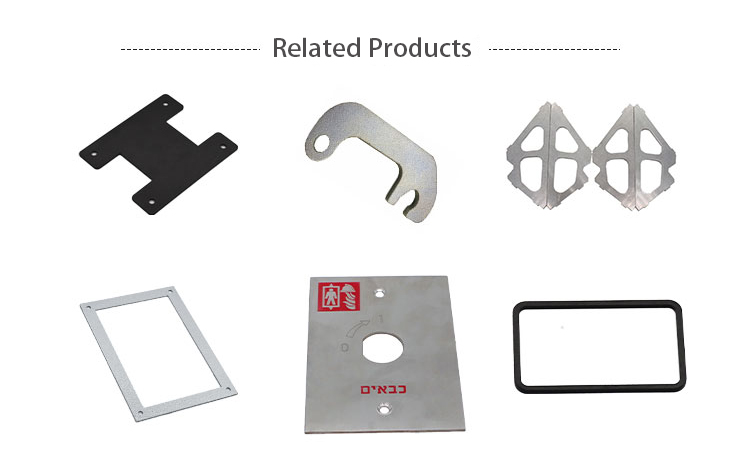

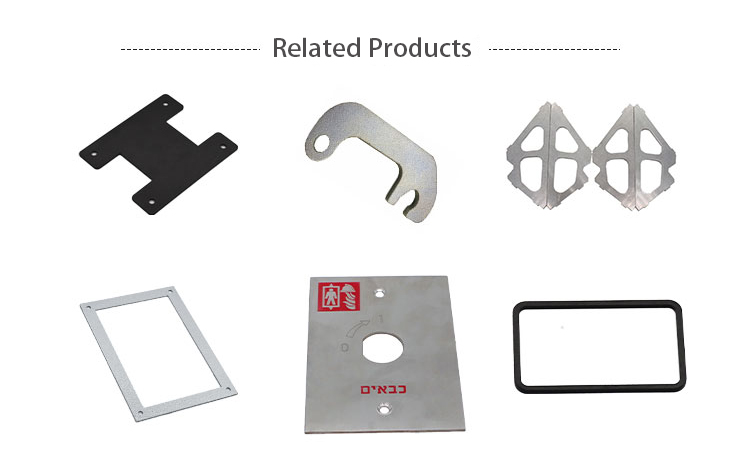

Versatility: Metal stamping can be used to produce a wide range of products, including automotive parts, electrical components, and household appliances.

Cost-effective: Metal stamping is a cost-effective manufacturing process, as it can produce large quantities of parts quickly and efficiently.

Different Types of Metal Stamping:

1. Progressive stamping: This method of metal stamping involves a series of dies that are utilized to shape and cut the metal sheet into the desired form.

2. Transfer stamping: This type of metal stamping involves transferring the metal sheet from one die to another until the final desired shape is achieved.

3. Single-stage stamping: This form of metal stamping involves using a single die to shape and cut the metal sheet into the desired form.

Surface Treatment

Metalli's stamping capability

● Product dimension up to Length*Width 1200*600 mm

● Wall thickness up to 12 mm

● Tolerance ±0.1 mm or less

● Tools design and manufacturing in house

● Multi-step tools design and manufacturing available to achieve high speed mass production pace with the lowest unit price

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum, brass,etc |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Stamping |

5 | Tolerance | +/-0.1mm |

6 | Surface treatment | Powder coating, galvanization, anodizing, etc |

7 | Application | Industry |

8 | Warranty time | 1-2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

Metal stamping is a manufacturing process that involves shaping and cutting metal sheets into desired shapes and sizes using a stamping press machine. The metal sheets are fed into the machine, where they are subjected to high pressure, which causes the metal to take the shape of the die.

Metal stamping is a precise and cost-effective manufacturing process that can create a wide range of products. It plays a crucial role in the manufacturing industry due to its versatility and various techniques employed. Typically, stamping is performed on cold metal sheets, while hot metal forming operations can be done through forging.

Features of Metal Stamping:

Precision: Metal stamping is a highly precise manufacturing process that can produce complex shapes and designs with accuracy and consistency.

Versatility: Metal stamping can be used to produce a wide range of products, including automotive parts, electrical components, and household appliances.

Cost-effective: Metal stamping is a cost-effective manufacturing process, as it can produce large quantities of parts quickly and efficiently.

Different Types of Metal Stamping:

1. Progressive stamping: This method of metal stamping involves a series of dies that are utilized to shape and cut the metal sheet into the desired form.

2. Transfer stamping: This type of metal stamping involves transferring the metal sheet from one die to another until the final desired shape is achieved.

3. Single-stage stamping: This form of metal stamping involves using a single die to shape and cut the metal sheet into the desired form.

Surface Treatment

Metalli's stamping capability

● Product dimension up to Length*Width 1200*600 mm

● Wall thickness up to 12 mm

● Tolerance ±0.1 mm or less

● Tools design and manufacturing in house

● Multi-step tools design and manufacturing available to achieve high speed mass production pace with the lowest unit price