- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum, brass,etc |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Stamping |

5 | Tolerance | +/-0.1mm |

6 | Surface treatment | Powder coating, galvanization, anodizing, etc |

7 | Application | Industry |

8 | Warranty time | 1-2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

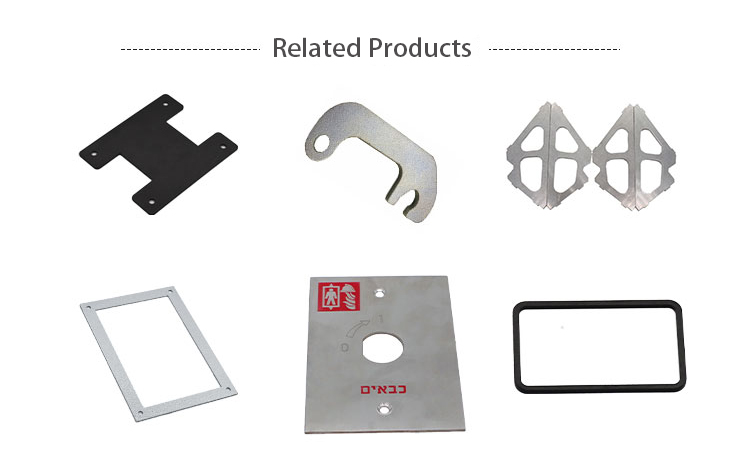

Copper Sheet Metal Stamping-The Versatile Manufacturing Process

Stamping is a sheet-metal forming process that involves shaping metal sheets into various shapes and sizes. This process is widely used in the manufacturing industry to create products that range from simple to complex designs. Copper sheet metal stamping is one of the most versatile and widely used stamping processes in the industry. In this article, we will explore the benefits and applications of copper sheet metal stamping.

Stamping is usually done on cold metal sheet. See Forging for hot metal forming operations.

Working Principle

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It is a complex process that can include a number of metal forming techniques - blanking, punching, bending and piercing

Metalli's stamping capability

● Can accommodate products with dimensions of up to 1200mm in length and 600mm in width.

● Capable of handling wall thicknesses up to 12mm.

● Maintains a tolerance level of ±0.1mm or less.

● Designs and manufactures tools in-house.

● Offers multi-step tool design and manufacturing to achieve high-speed mass production at the lowest unit price.

More Fabrication Options

Applications:

1. Automotive industry: Metal stamping is widely used in the automotive industry to produce parts and components such as body panels, engine components, and suspension parts.

2. Aerospace industry: This process is used to produce parts and components for aircraft such as wing panels, engine components, and landing gear parts.

3. Electronics industry: Metal stamping is used to produce parts for electronic devices such as computer components, mobile phones, and home appliances.

4. Construction industry: This process is used to produce parts and components for construction equipment, such as excavators, bulldozers, and cranes.

Surface Treatment

Benefits of Copper Sheet Metal Stamping

Copper sheet metal stamping offers a range of benefits that make it an ideal manufacturing process for a variety of applications. Some of the benefits of copper sheet metal stamping include:

1. Versatility: Copper sheet metal stamping can be used to create a wide range of shapes and sizes, making it a versatile manufacturing process.

2. Precision: Copper sheet metal stamping allows for high precision and accuracy, ensuring that the final product meets the required specifications.

3. Cost-effective: Copper sheet metal stamping is a cost-effective manufacturing process, as it allows for high-volume production at a low cost.

4. Durability: Copper is a durable material that is resistant to corrosion, making it an ideal material for a range of applications.

Safe Package Before Shipping

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum, brass,etc |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Stamping |

5 | Tolerance | +/-0.1mm |

6 | Surface treatment | Powder coating, galvanization, anodizing, etc |

7 | Application | Industry |

8 | Warranty time | 1-2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

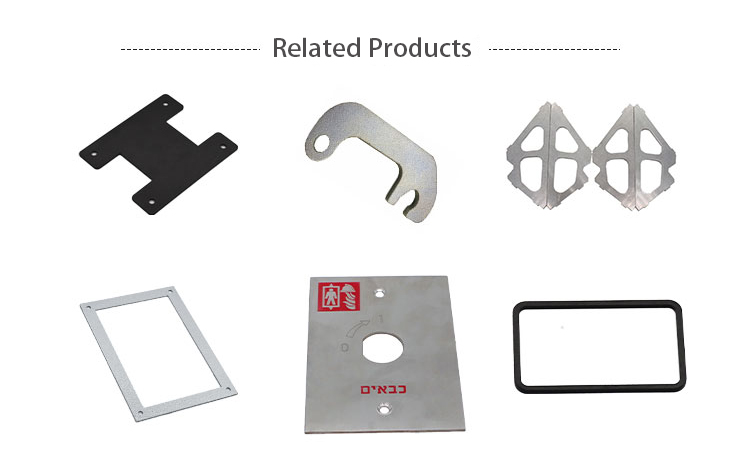

Copper Sheet Metal Stamping-The Versatile Manufacturing Process

Stamping is a sheet-metal forming process that involves shaping metal sheets into various shapes and sizes. This process is widely used in the manufacturing industry to create products that range from simple to complex designs. Copper sheet metal stamping is one of the most versatile and widely used stamping processes in the industry. In this article, we will explore the benefits and applications of copper sheet metal stamping.

Stamping is usually done on cold metal sheet. See Forging for hot metal forming operations.

Working Principle

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It is a complex process that can include a number of metal forming techniques - blanking, punching, bending and piercing

Metalli's stamping capability

● Can accommodate products with dimensions of up to 1200mm in length and 600mm in width.

● Capable of handling wall thicknesses up to 12mm.

● Maintains a tolerance level of ±0.1mm or less.

● Designs and manufactures tools in-house.

● Offers multi-step tool design and manufacturing to achieve high-speed mass production at the lowest unit price.

More Fabrication Options

Applications:

1. Automotive industry: Metal stamping is widely used in the automotive industry to produce parts and components such as body panels, engine components, and suspension parts.

2. Aerospace industry: This process is used to produce parts and components for aircraft such as wing panels, engine components, and landing gear parts.

3. Electronics industry: Metal stamping is used to produce parts for electronic devices such as computer components, mobile phones, and home appliances.

4. Construction industry: This process is used to produce parts and components for construction equipment, such as excavators, bulldozers, and cranes.

Surface Treatment

Benefits of Copper Sheet Metal Stamping

Copper sheet metal stamping offers a range of benefits that make it an ideal manufacturing process for a variety of applications. Some of the benefits of copper sheet metal stamping include:

1. Versatility: Copper sheet metal stamping can be used to create a wide range of shapes and sizes, making it a versatile manufacturing process.

2. Precision: Copper sheet metal stamping allows for high precision and accuracy, ensuring that the final product meets the required specifications.

3. Cost-effective: Copper sheet metal stamping is a cost-effective manufacturing process, as it allows for high-volume production at a low cost.

4. Durability: Copper is a durable material that is resistant to corrosion, making it an ideal material for a range of applications.

Safe Package Before Shipping