- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum, brass,etc |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Stamping |

5 | Tolerance | +/-0.1mm |

6 | Surface treatment | Powder coating, galvanization, anodizing, etc |

7 | Application | Industry |

8 | Warranty time | 1-2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

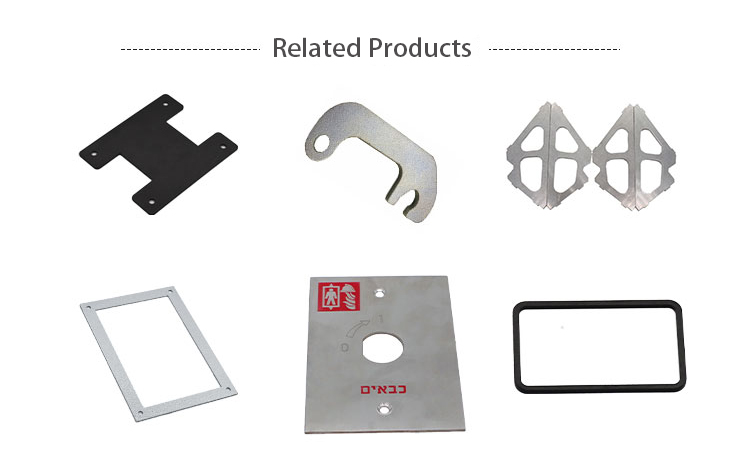

Product Display

The process of metal stamping in manufacturing allows for the quick and clean production of solid metal parts and shapes. By utilizing specialized dies, sheets of metal are pressed into precise forms. The automotive industry finds metal stamping particularly advantageous for components like fenders and hub caps, as the dies can be reused to consistently produce parts that meet strict specifications and tolerances.

Metal stamping offers several key advantages:

Cost-Effectiveness: Once the dies are created, manufacturers can produce large quantities of automotive parts at a low cost.

Efficient Use of Materials: Metal stamping utilizes sheet metal, which is efficient and does not add unnecessary weight or thickness to the part.

Automation: Metal stamping processes can be fully automated, reducing the risk of human error or inconsistency. This not only lowers labor costs but also ensures employee safety.

Metalli's ability to stamp:

● Can accommodate products with dimensions of up to 1200 mm in length and 600 mm in width.

● Can handle wall thicknesses of up to 12 mm.

● Maintains a tolerance of ±0.1 mm or even less.

● Designs and manufactures tools internally.

● Offers the option of designing and manufacturing multi-step tools to achieve high-speed mass production and the most affordable unit price.

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum, brass,etc |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20 mm |

4 | Process | Stamping |

5 | Tolerance | +/-0.1mm |

6 | Surface treatment | Powder coating, galvanization, anodizing, etc |

7 | Application | Industry |

8 | Warranty time | 1-2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

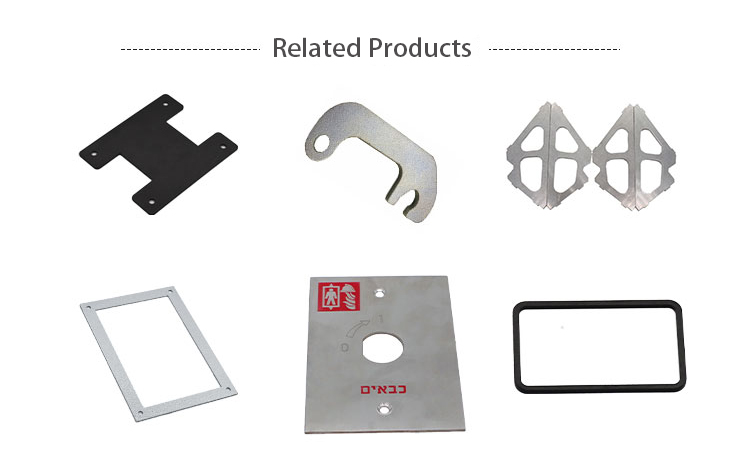

Product Display

The process of metal stamping in manufacturing allows for the quick and clean production of solid metal parts and shapes. By utilizing specialized dies, sheets of metal are pressed into precise forms. The automotive industry finds metal stamping particularly advantageous for components like fenders and hub caps, as the dies can be reused to consistently produce parts that meet strict specifications and tolerances.

Metal stamping offers several key advantages:

Cost-Effectiveness: Once the dies are created, manufacturers can produce large quantities of automotive parts at a low cost.

Efficient Use of Materials: Metal stamping utilizes sheet metal, which is efficient and does not add unnecessary weight or thickness to the part.

Automation: Metal stamping processes can be fully automated, reducing the risk of human error or inconsistency. This not only lowers labor costs but also ensures employee safety.

Metalli's ability to stamp:

● Can accommodate products with dimensions of up to 1200 mm in length and 600 mm in width.

● Can handle wall thicknesses of up to 12 mm.

● Maintains a tolerance of ±0.1 mm or even less.

● Designs and manufactures tools internally.

● Offers the option of designing and manufacturing multi-step tools to achieve high-speed mass production and the most affordable unit price.