- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

Product name : water cooling copper block liquid cooler system

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Pure copper T2 |

2 | Dimension (L*W*T) | Up to 500*500*15 mm |

3 | Cooling Capacity | 1000 to 3000 W |

4 | Working Pressure | 3 to 4 bars |

5 | Flatness | 0.15 mm |

6 | Surface roughness | 3.2 um |

7 | Flow rate | 5 to 10 L/min |

8 | Manufacturing Method | CNC machining Plus vacuum brazing |

9 | Joining Method | Vacuum Brazing |

10 | Cooling Method | Liquid cooling |

11 | Surface Finish | Mill finish |

12 | Coolant | Deionized Water,Inhibited Glycol and Water,Dielectric fluid |

13 | Warranty time | 1 year |

14 | Place of Region | Jiangsu province of China |

15 | Reference Standard | GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

Metalli’s cold plate technologies include

◆ Vacuum brazed or controlled atmosphere brazed and CNC machined performance fin cold plates and chassis

◆ Friction Stir Welded (FSW) performance-fin cold plates and chassis

◆ flat tube cold plates

◆ Press lock Copper tubed cold plates

◆ Vacuum brazed and CNC machined copper cold plates

◆ Stamped and vacuum brazed cold plates

◆ Gun-drilled custom cold plate

◆ Custom channeled cold plate with ladder configuration

◆ Inner-Finned Brazed Cold Plates

◆ Aluminum extruded and welded or brazed cold plate

◆ Aluminum die casting and welded or brazed cold plate

▲ Components for vacuum brazed cold plate

▲ Stamped and vacuum brazed cold plate

▲ Copper tubed cold plate

Introduction of a liquid cooling system

A liquid cooling system is a hydraulic circuit that typically consists of a cold plate that interfaces with the heat source, a pump that circulates the fluid through the system, and a heat exchanger that rejects the heat absorbed by the liquid from the device.

Liquid cooling systems are used in a variety of applications, including:

1. Gaming: High-performance gaming PCs generate a lot of heat, which can lead to reduced performance and even damage to components. Liquid cooling systems are used to keep gaming PCs cool and running at optimal performance.

2. Overclocking: Overclocking involves increasing the clock speed of computer components to achieve higher performance. This generates a lot of heat, which can be effectively dissipated using a liquid cooling system.

3. Workstations: Workstations used for tasks such as video editing and 3D rendering require high-performance components that generate a lot of heat. Liquid cooling systems are used to keep these components cool and prevent damage.

▲ Thermal simulation for cold plate

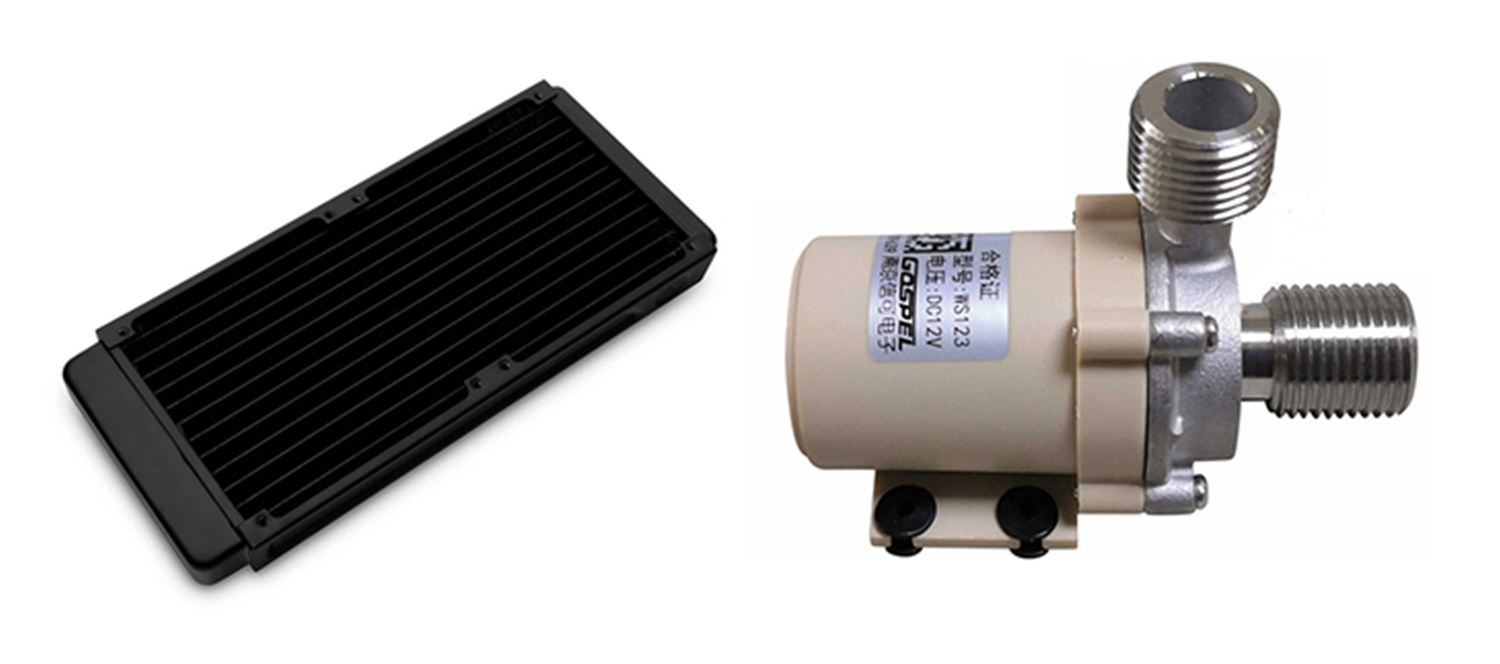

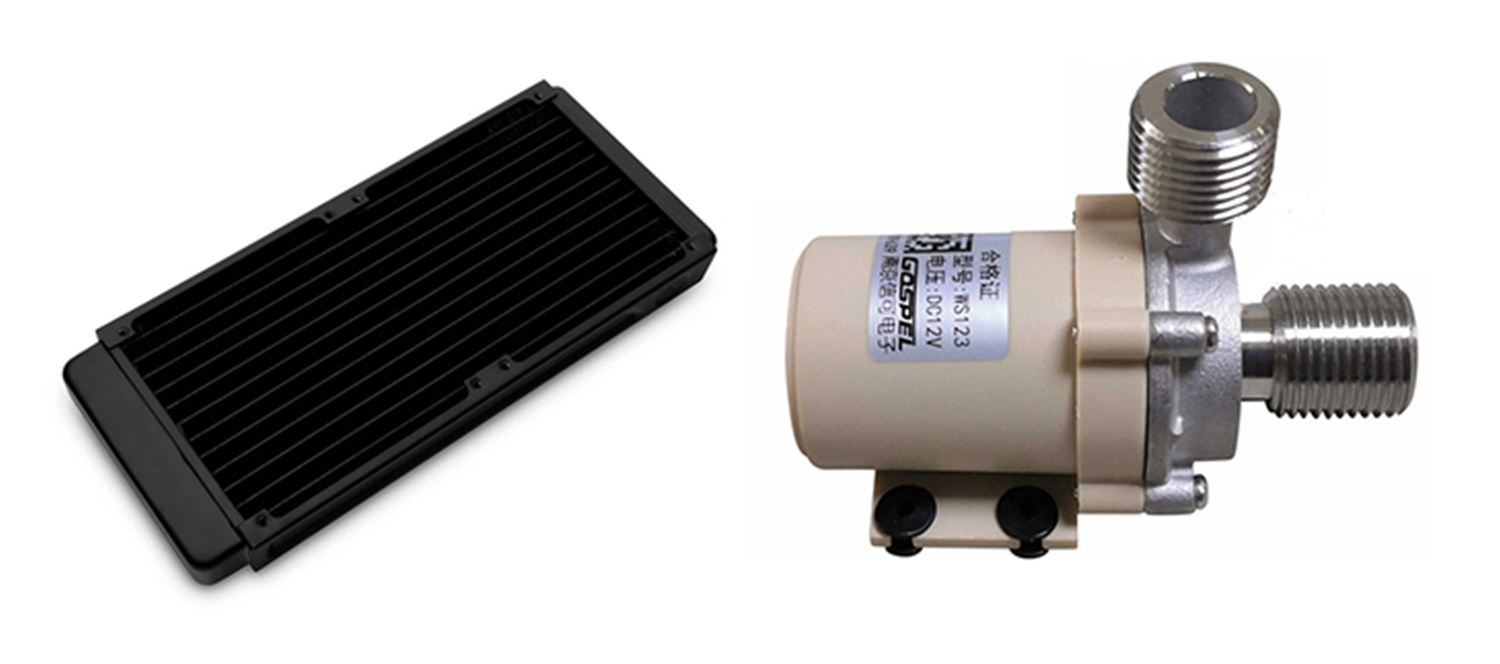

We also supply value added components as below

● Fittings and connectors

● Hoses and tubes

● Heat exchangers or radiators

● Pumps and reservoirs

● Fans

● Other accessories

▲ Radiator ▲ Pump

Product name : water cooling copper block liquid cooler system

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Pure copper T2 |

2 | Dimension (L*W*T) | Up to 500*500*15 mm |

3 | Cooling Capacity | 1000 to 3000 W |

4 | Working Pressure | 3 to 4 bars |

5 | Flatness | 0.15 mm |

6 | Surface roughness | 3.2 um |

7 | Flow rate | 5 to 10 L/min |

8 | Manufacturing Method | CNC machining Plus vacuum brazing |

9 | Joining Method | Vacuum Brazing |

10 | Cooling Method | Liquid cooling |

11 | Surface Finish | Mill finish |

12 | Coolant | Deionized Water,Inhibited Glycol and Water,Dielectric fluid |

13 | Warranty time | 1 year |

14 | Place of Region | Jiangsu province of China |

15 | Reference Standard | GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

Metalli’s cold plate technologies include

◆ Vacuum brazed or controlled atmosphere brazed and CNC machined performance fin cold plates and chassis

◆ Friction Stir Welded (FSW) performance-fin cold plates and chassis

◆ flat tube cold plates

◆ Press lock Copper tubed cold plates

◆ Vacuum brazed and CNC machined copper cold plates

◆ Stamped and vacuum brazed cold plates

◆ Gun-drilled custom cold plate

◆ Custom channeled cold plate with ladder configuration

◆ Inner-Finned Brazed Cold Plates

◆ Aluminum extruded and welded or brazed cold plate

◆ Aluminum die casting and welded or brazed cold plate

▲ Components for vacuum brazed cold plate

▲ Stamped and vacuum brazed cold plate

▲ Copper tubed cold plate

Introduction of a liquid cooling system

A liquid cooling system is a hydraulic circuit that typically consists of a cold plate that interfaces with the heat source, a pump that circulates the fluid through the system, and a heat exchanger that rejects the heat absorbed by the liquid from the device.

Liquid cooling systems are used in a variety of applications, including:

1. Gaming: High-performance gaming PCs generate a lot of heat, which can lead to reduced performance and even damage to components. Liquid cooling systems are used to keep gaming PCs cool and running at optimal performance.

2. Overclocking: Overclocking involves increasing the clock speed of computer components to achieve higher performance. This generates a lot of heat, which can be effectively dissipated using a liquid cooling system.

3. Workstations: Workstations used for tasks such as video editing and 3D rendering require high-performance components that generate a lot of heat. Liquid cooling systems are used to keep these components cool and prevent damage.

▲ Thermal simulation for cold plate

We also supply value added components as below

● Fittings and connectors

● Hoses and tubes

● Heat exchangers or radiators

● Pumps and reservoirs

● Fans

● Other accessories

▲ Radiator ▲ Pump