- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | A6063 T5 |

2 | Dimension L*W*H | 60*60mm |

3 | Wall Thickness | 3 mm |

4 | Process | Extrusion |

5 | Tolerance | +/-0.15mm |

6 | Surface treatment | Brushed bronze anodizing |

7 | Application | Architecture |

8 | Extruder | 1000 Tons |

9 | Cutting length | 5 meters/pc |

10 | Weight per meter | 0.95kg/m |

Product CAD drawing

Metalli’s Aluminum Extrusion capabilities

◆ Maximum product section dimension 500*500 mm

◆ Length up to 6 meters

◆ Wall thickness minimal to 0.2 mm

◆ Over 50 press machines from 100 tons to 6800 tons

◆ Further process like machining, stamping is available in house

◆ Tools design and manufacturing in house

◆ Surface treatment anodization and powder coating available in house

◆ Typical aluminum alloys like 1070, 3003, 6061,6063 or other custom alloys are available

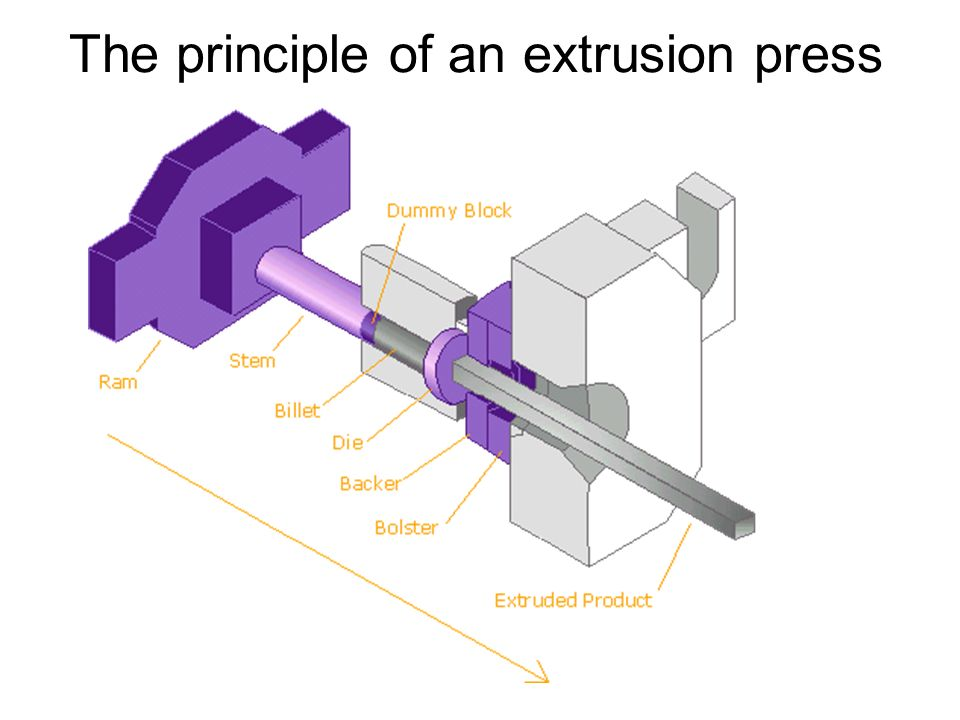

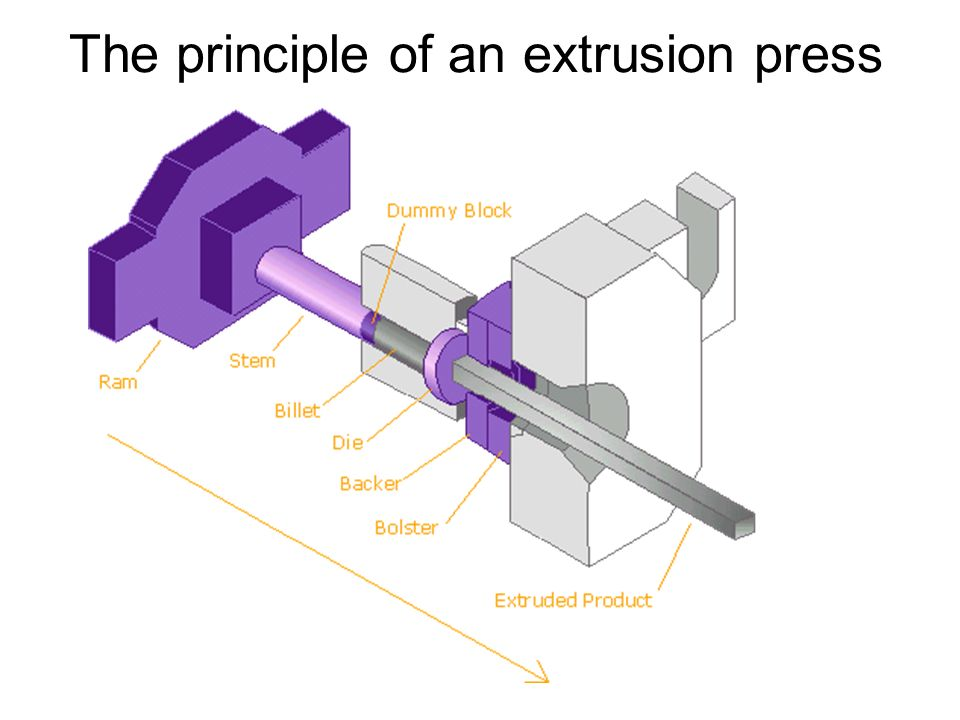

Brief of aluminum extrusion

Extrusion is defined as the process of shaping material, such as aluminum, by forcing it to flow through a shaped opening in a die. Extruded material emerges as an elongated piece with the same profile as the die opening.

Aluminum is particularly well suited to the extrusion process due to its excellent plasticity at extrusion temperature. Only a minor degree of work-hardening takes place at this temperature and sufficient hot work is performed to improved the metallurgical structure of the extruded shape.

Aluminum extrusion is a process by which aluminum alloy material is forced through a die with a specific cross-sectional profile. A powerful ram pushes the aluminum through the die and it emerges from the die opening. When it does, it comes out in the same shape as the die and is pulled out along a runout table.

There are three main categories of extruded shapes:

Solid, with no enclosed voids or openings (i.e. a rod, beam, or angle).

Hollow, with one or more voids (i.e. square or rectangular tube).

Semi-hollow, with a partially enclosed void (i.e. a “C” channel with a narrow gap)

(Related: Aluminum Extrusion Dies: This is What Designers Should Know)

Extrusion has innumerable applications across many different industries, including the architectural, automotive, electronics, aerospace, energy, and other industries.

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | A6063 T5 |

2 | Dimension L*W*H | 60*60mm |

3 | Wall Thickness | 3 mm |

4 | Process | Extrusion |

5 | Tolerance | +/-0.15mm |

6 | Surface treatment | Brushed bronze anodizing |

7 | Application | Architecture |

8 | Extruder | 1000 Tons |

9 | Cutting length | 5 meters/pc |

10 | Weight per meter | 0.95kg/m |

Product CAD drawing

Metalli’s Aluminum Extrusion capabilities

◆ Maximum product section dimension 500*500 mm

◆ Length up to 6 meters

◆ Wall thickness minimal to 0.2 mm

◆ Over 50 press machines from 100 tons to 6800 tons

◆ Further process like machining, stamping is available in house

◆ Tools design and manufacturing in house

◆ Surface treatment anodization and powder coating available in house

◆ Typical aluminum alloys like 1070, 3003, 6061,6063 or other custom alloys are available

Brief of aluminum extrusion

Extrusion is defined as the process of shaping material, such as aluminum, by forcing it to flow through a shaped opening in a die. Extruded material emerges as an elongated piece with the same profile as the die opening.

Aluminum is particularly well suited to the extrusion process due to its excellent plasticity at extrusion temperature. Only a minor degree of work-hardening takes place at this temperature and sufficient hot work is performed to improved the metallurgical structure of the extruded shape.

Aluminum extrusion is a process by which aluminum alloy material is forced through a die with a specific cross-sectional profile. A powerful ram pushes the aluminum through the die and it emerges from the die opening. When it does, it comes out in the same shape as the die and is pulled out along a runout table.

There are three main categories of extruded shapes:

Solid, with no enclosed voids or openings (i.e. a rod, beam, or angle).

Hollow, with one or more voids (i.e. square or rectangular tube).

Semi-hollow, with a partially enclosed void (i.e. a “C” channel with a narrow gap)

(Related: Aluminum Extrusion Dies: This is What Designers Should Know)

Extrusion has innumerable applications across many different industries, including the architectural, automotive, electronics, aerospace, energy, and other industries.