- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | A6063 T5 |

2 | Dimension | 80*40mm |

3 | Wall Thickness | 2.5 mm |

4 | Process | Extrusion+Bening |

5 | Tolerance | +/-0.15mm |

6 | Surface treatment | Powder coating white |

7 | Application | Touchless swift dryer |

8 | Extruder | 1000 Tons |

9 | Bending radian | |

10 | Weight per piece | 0.8kg/pc |

Product Display

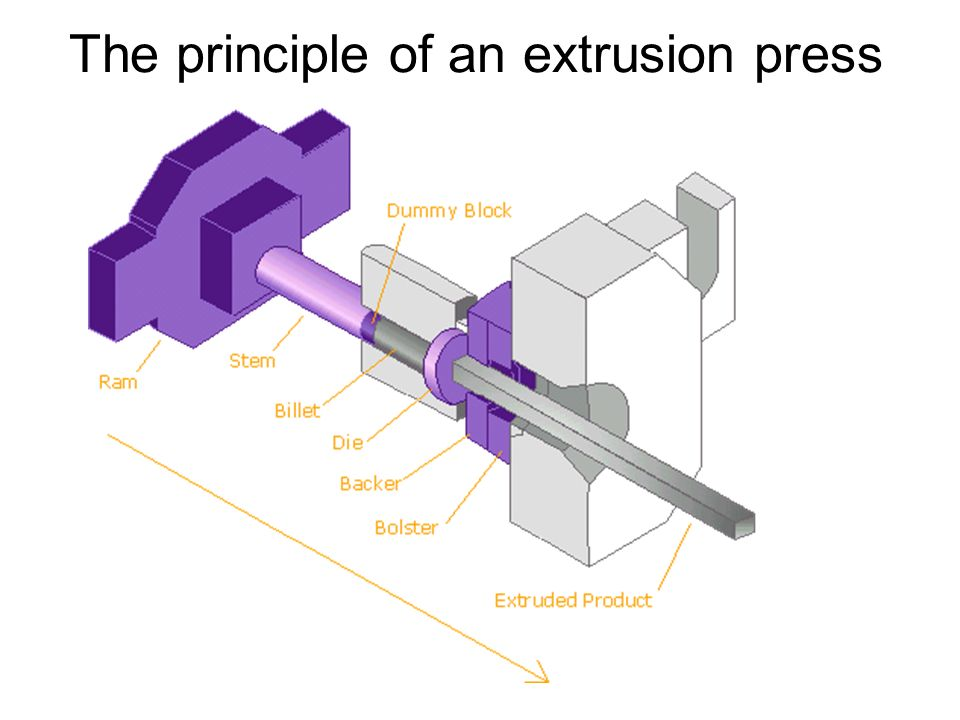

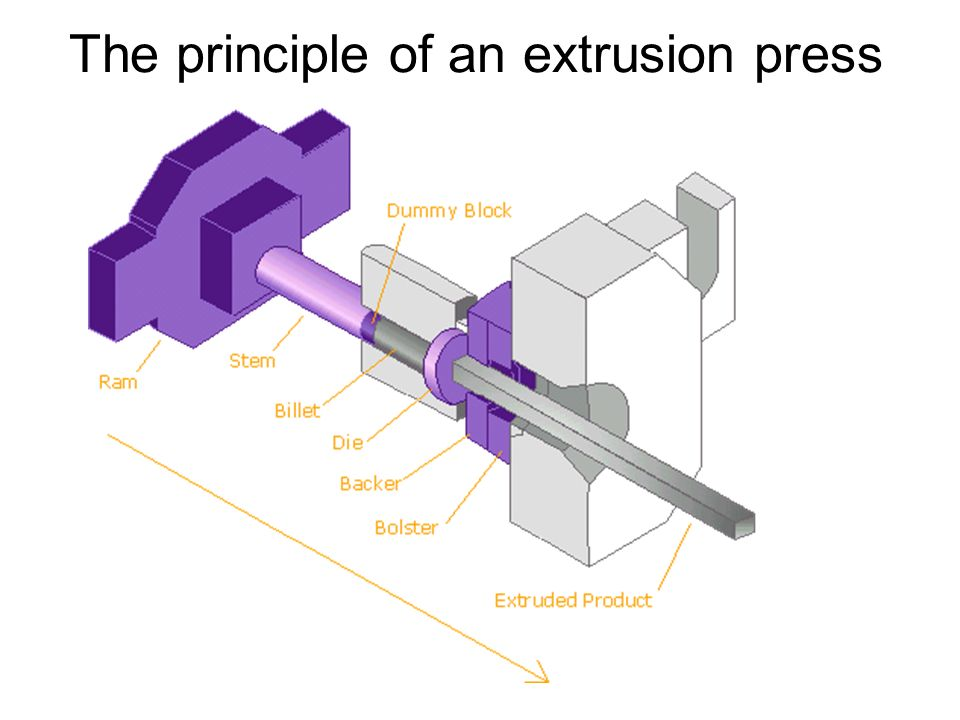

Brief of aluminum extrusion

The process of shaping aluminum material by pushing it through a die with a specific cross-sectional shape is known as aluminum extrusion. This method is ideal for aluminum because it is highly malleable at extrusion temperature. The resulting extruded material takes on the same shape as the die opening and is pulled out on a runout table. There are three main types of extruded shapes: solid, hollow, and semi-hollow. Extrusion is widely used in industries such as architecture, automotive, electronics, aerospace, and energy.

Metalli's Aluminum Extrusion capabilities

◆ Maximum product section dimension 500*500 mm

◆ Length up to 6 meters

◆ Wall thickness minimal to 0.2 mm

◆ Over 50 press machines from 100 tons to 6800 tons

◆ Further process like machining, stamping is available in house

◆ Tools design and manufacturing in house

◆ Surface treatment anodization and powder coating available in house

◆ Typical aluminum alloys like 1070, 3003, 6061,6063 or other custom alloys are available

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | A6063 T5 |

2 | Dimension | 80*40mm |

3 | Wall Thickness | 2.5 mm |

4 | Process | Extrusion+Bening |

5 | Tolerance | +/-0.15mm |

6 | Surface treatment | Powder coating white |

7 | Application | Touchless swift dryer |

8 | Extruder | 1000 Tons |

9 | Bending radian | |

10 | Weight per piece | 0.8kg/pc |

Product Display

Brief of aluminum extrusion

The process of shaping aluminum material by pushing it through a die with a specific cross-sectional shape is known as aluminum extrusion. This method is ideal for aluminum because it is highly malleable at extrusion temperature. The resulting extruded material takes on the same shape as the die opening and is pulled out on a runout table. There are three main types of extruded shapes: solid, hollow, and semi-hollow. Extrusion is widely used in industries such as architecture, automotive, electronics, aerospace, and energy.

Metalli's Aluminum Extrusion capabilities

◆ Maximum product section dimension 500*500 mm

◆ Length up to 6 meters

◆ Wall thickness minimal to 0.2 mm

◆ Over 50 press machines from 100 tons to 6800 tons

◆ Further process like machining, stamping is available in house

◆ Tools design and manufacturing in house

◆ Surface treatment anodization and powder coating available in house

◆ Typical aluminum alloys like 1070, 3003, 6061,6063 or other custom alloys are available