- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum, etc |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20mm |

4 | Process | Bending |

5 | Tolerance | +/-0.2mm |

6 | Surface treatment | Powder coating, galvanization, anodizing |

7 | Application | Industry |

8 | Warranty time | 1-2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

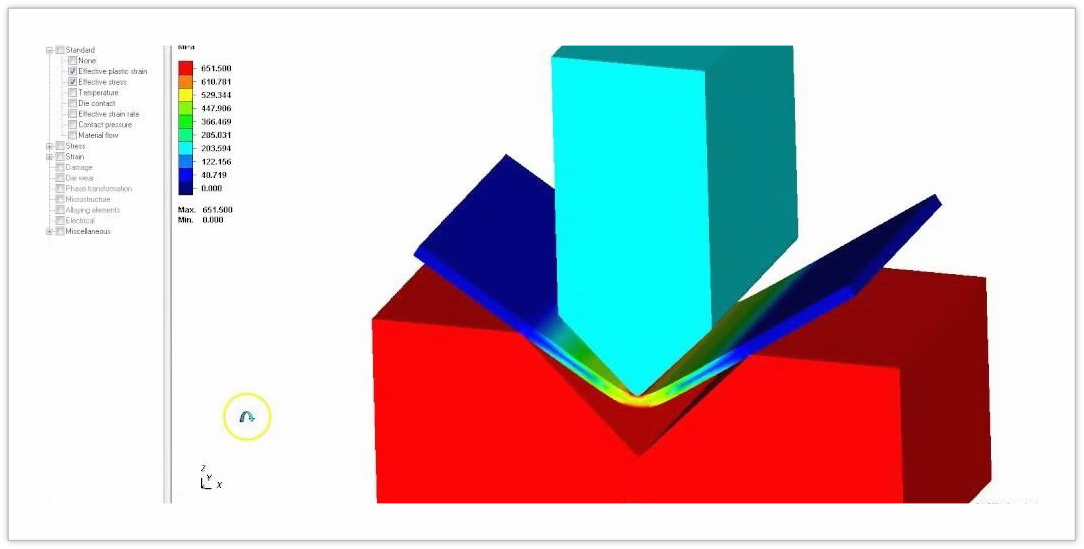

The bending process in sheet metal operations is a manufacturing technique used to deform metal sheets into a desired shape by applying force. It involves plastically deforming the sheet material around a straight axis without changing the sheet's thickness. Bending is used to create various geometries such as channels, V-shapes, U-shapes, or other angles.

Key Steps in the Bending Process:

Clamping the Sheet Metal: The sheet is securely held in place, usually on a die, to ensure it doesn’t slip during the process.

Application of Force: A punch or press tool applies force, causing the sheet to bend at a specific angle. The punch is typically matched with a corresponding die (tooling) to ensure the desired shape.

Elastic Recovery (Springback): After the bending force is removed, the sheet may spring back slightly, which is called "springback." This is an elastic recovery that must be considered when designing the process.

Final Shape: The sheet metal retains its bent shape once the elastic limit is exceeded during the bending process.

Bending is widely used in industries to manufacture components such as brackets, enclosures, and frames.

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Mild steel, stainless steel, aluminum, etc |

2 | Dimension L*W*H | Common 0.5mm-1000mm |

3 | Thickness of material | Common 0.2mm-20mm |

4 | Process | Bending |

5 | Tolerance | +/-0.2mm |

6 | Surface treatment | Powder coating, galvanization, anodizing |

7 | Application | Industry |

8 | Warranty time | 1-2 year(s) |

9 | Place of Region | Jiangsu province of China |

10 | Samples service | Available |

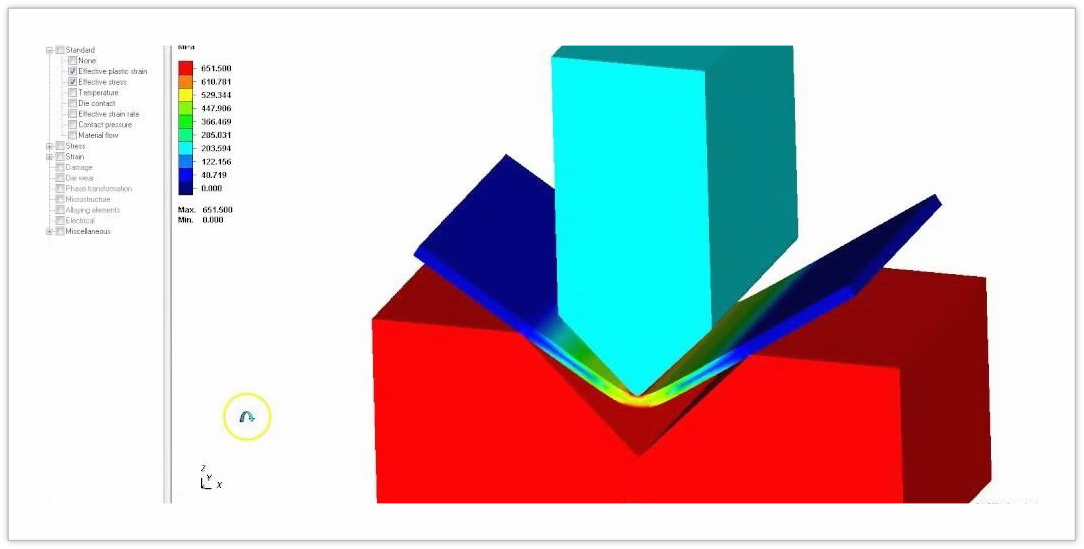

The bending process in sheet metal operations is a manufacturing technique used to deform metal sheets into a desired shape by applying force. It involves plastically deforming the sheet material around a straight axis without changing the sheet's thickness. Bending is used to create various geometries such as channels, V-shapes, U-shapes, or other angles.

Key Steps in the Bending Process:

Clamping the Sheet Metal: The sheet is securely held in place, usually on a die, to ensure it doesn’t slip during the process.

Application of Force: A punch or press tool applies force, causing the sheet to bend at a specific angle. The punch is typically matched with a corresponding die (tooling) to ensure the desired shape.

Elastic Recovery (Springback): After the bending force is removed, the sheet may spring back slightly, which is called "springback." This is an elastic recovery that must be considered when designing the process.

Final Shape: The sheet metal retains its bent shape once the elastic limit is exceeded during the bending process.

Bending is widely used in industries to manufacture components such as brackets, enclosures, and frames.