- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

Product name : electronic components cpu gpu aluminum liquid clod block plate water cooling heatsink

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Aluminum alloy 3003, 6063,6061 |

2 | Dimension (L*W*T) | Up to 500*500*15 mm |

3 | Cooling Capacity | 500 to 1500 W |

4 | Working Pressure | 3 to 4 bars |

5 | Flatness | 0.15 mm |

6 | Surface roughness | 3.2 um |

7 | Flow rate | 5 to 10 L/min |

8 | Manufacturing Method | CNC machining Plus vacuum brazing |

9 | Joining Method | Vacuum Brazing |

10 | Cooling Method | Liquid cooling |

11 | Surface Finish | Mill finish or anodization |

12 | Coolant | Deionized Water,Inhibited Glycol and Water,Dielectric fluid |

13 | Warranty time | 1 year |

14 | Place of Region | Jiangsu province of China |

15 | Reference Standard | GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

Metalli offers a wide range of cold plate technologies to meet the specific needs of different applications. These include vacuum brazed or controlled atmosphere brazed and CNC machined performance fin cold plates and chassis, which are designed for high heat transfer efficiency and optimized performance.

Friction Stir Welded (FSW) performance-fin cold plates and chassis are also available, which offer enhanced strength and durability. Flat tube cold plates, press lock copper tubed cold plates, and vacuum brazed and CNC machined copper cold plates are also offered, each with their own unique benefits and applications.

Stamped and vacuum brazed cold plates, gun-drilled custom cold plates, and custom channeled cold plate with ladder configuration are other options available from Metalli. Inner-Finned Brazed Cold Plates, aluminum extruded and welded or brazed cold plates, and aluminum die casting and welded or brazed cold plates are also part of the range of cold plate technologies offered by Metalli.

▲ Components for vacuum brazed cold plate

▲ Stamped and vacuum brazed cold plate

▲ Copper tubed cold plate

We also supply value added components as below

● Fittings and connectors

● Hoses and tubes

● Heat exchangers or radiators

● Pumps and reservoirs

● Fans

● Other accessories

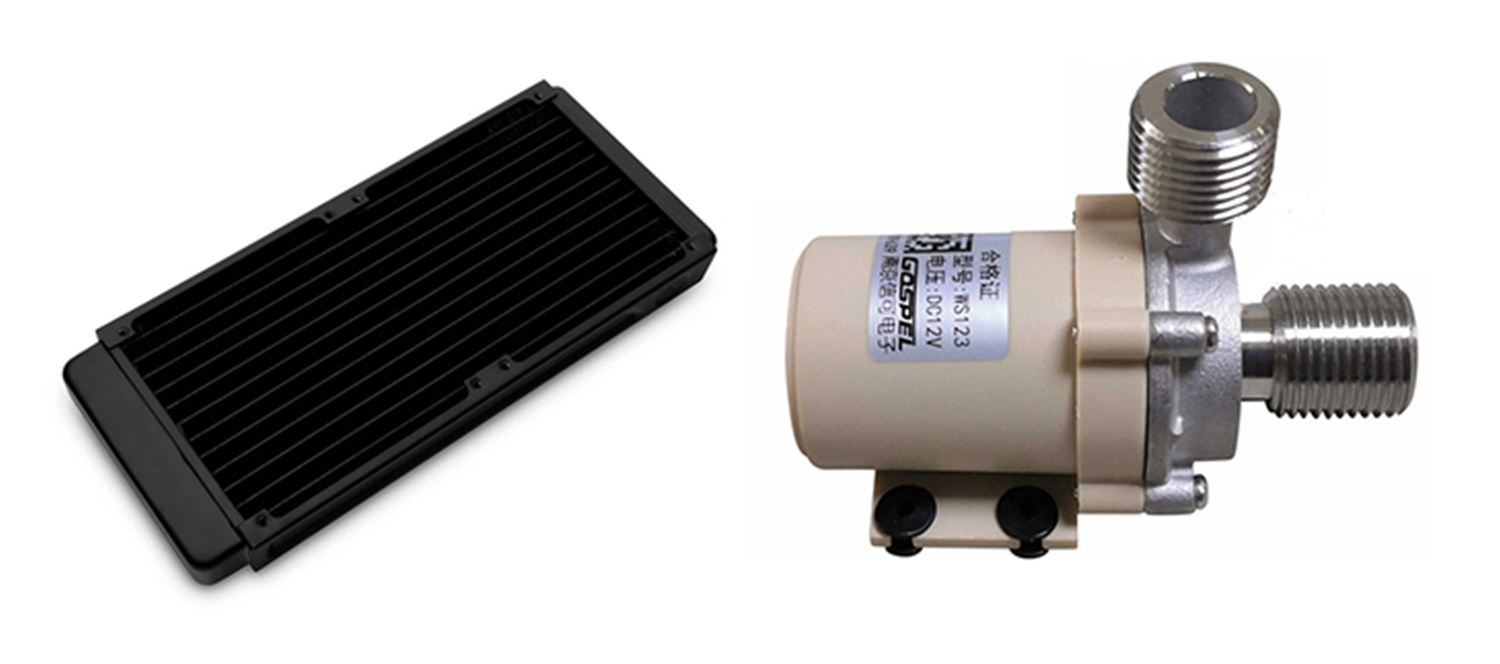

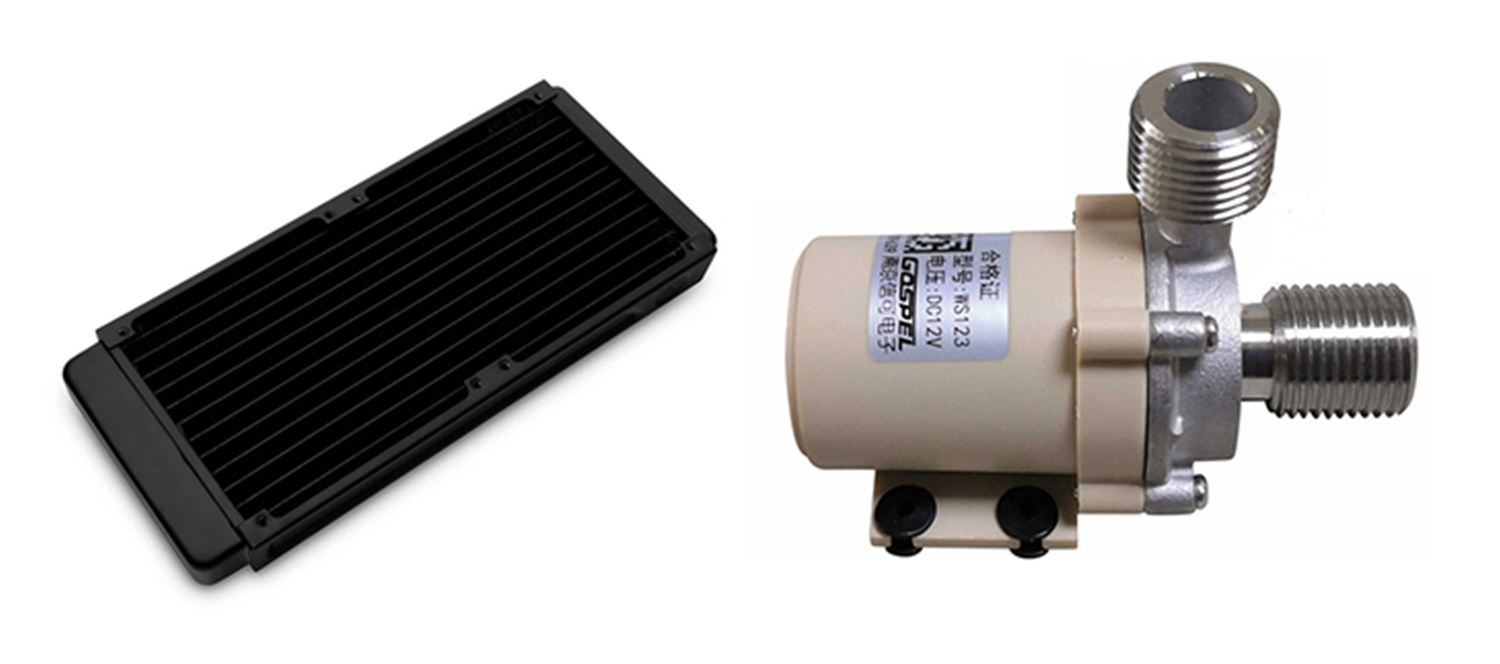

▲ Radiator ▲ Pump

Brief of a liquid cooling system

The cold plate is connected to a pump, which circulates a liquid coolant through the system. The coolant absorbs heat from the cold plate and carries it away from the heat source. The coolant is then passed through a radiator or other heat exchanger, which dissipates the heat into the surrounding environment. The cooled coolant is then returned to the cold plate to repeat the cycle.

The liquid coolant used in a liquid cooling system can vary depending on the application. Common coolants include water, ethylene glycol, and various types of oils. The choice of coolant will depend on factors such as the operating temperature range, heat transfer efficiency, and compatibility with other system components.

Liquid cooling systems are commonly used in high-performance computing, gaming, and overclocking applications where air cooling is insufficient to keep the system cool. They can also be used in industrial and automotive applications where high heat loads need to be dissipated.

Overall, liquid cooling systems offer superior heat dissipation compared to air cooling systems, allowing for higher performance and longer component lifespan. However, they can be more complex and expensive to install and maintain.

Product name : electronic components cpu gpu aluminum liquid clod block plate water cooling heatsink

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Aluminum alloy 3003, 6063,6061 |

2 | Dimension (L*W*T) | Up to 500*500*15 mm |

3 | Cooling Capacity | 500 to 1500 W |

4 | Working Pressure | 3 to 4 bars |

5 | Flatness | 0.15 mm |

6 | Surface roughness | 3.2 um |

7 | Flow rate | 5 to 10 L/min |

8 | Manufacturing Method | CNC machining Plus vacuum brazing |

9 | Joining Method | Vacuum Brazing |

10 | Cooling Method | Liquid cooling |

11 | Surface Finish | Mill finish or anodization |

12 | Coolant | Deionized Water,Inhibited Glycol and Water,Dielectric fluid |

13 | Warranty time | 1 year |

14 | Place of Region | Jiangsu province of China |

15 | Reference Standard | GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

Metalli offers a wide range of cold plate technologies to meet the specific needs of different applications. These include vacuum brazed or controlled atmosphere brazed and CNC machined performance fin cold plates and chassis, which are designed for high heat transfer efficiency and optimized performance.

Friction Stir Welded (FSW) performance-fin cold plates and chassis are also available, which offer enhanced strength and durability. Flat tube cold plates, press lock copper tubed cold plates, and vacuum brazed and CNC machined copper cold plates are also offered, each with their own unique benefits and applications.

Stamped and vacuum brazed cold plates, gun-drilled custom cold plates, and custom channeled cold plate with ladder configuration are other options available from Metalli. Inner-Finned Brazed Cold Plates, aluminum extruded and welded or brazed cold plates, and aluminum die casting and welded or brazed cold plates are also part of the range of cold plate technologies offered by Metalli.

▲ Components for vacuum brazed cold plate

▲ Stamped and vacuum brazed cold plate

▲ Copper tubed cold plate

We also supply value added components as below

● Fittings and connectors

● Hoses and tubes

● Heat exchangers or radiators

● Pumps and reservoirs

● Fans

● Other accessories

▲ Radiator ▲ Pump

Brief of a liquid cooling system

The cold plate is connected to a pump, which circulates a liquid coolant through the system. The coolant absorbs heat from the cold plate and carries it away from the heat source. The coolant is then passed through a radiator or other heat exchanger, which dissipates the heat into the surrounding environment. The cooled coolant is then returned to the cold plate to repeat the cycle.

The liquid coolant used in a liquid cooling system can vary depending on the application. Common coolants include water, ethylene glycol, and various types of oils. The choice of coolant will depend on factors such as the operating temperature range, heat transfer efficiency, and compatibility with other system components.

Liquid cooling systems are commonly used in high-performance computing, gaming, and overclocking applications where air cooling is insufficient to keep the system cool. They can also be used in industrial and automotive applications where high heat loads need to be dissipated.

Overall, liquid cooling systems offer superior heat dissipation compared to air cooling systems, allowing for higher performance and longer component lifespan. However, they can be more complex and expensive to install and maintain.