- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

Product name : Cnc Machined custom Aluminium Cooling Block ev battery cooling liquid cold plate

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Aluminum alloy 3003, 6063,6061 |

2 | Dimension (L*W*T) | Up to 500*500*15 mm |

3 | Cooling Capacity | 500 to 1500 W |

4 | Working Pressure | 3 to 4 bars |

5 | Flatness | 0.15 mm |

6 | Surface roughness | 3.2 um |

7 | Flow rate | 5 to 10 L/min |

8 | Manufacturing Method | CNC machining Plus vacuum brazing |

9 | Joining Method | Vacuum Brazing |

10 | Cooling Method | Liquid cooling |

11 | Surface Finish | Mill finish or anodization |

12 | Coolant | Deionized Water,Inhibited Glycol and Water,Dielectric fluid |

13 | Warranty time | 1 year |

14 | Place of Region | Jiangsu province of China |

15 | Reference Standard | GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

Metalli provides a range of cold plate options, including vacuum brazed or controlled atmosphere brazed and CNC machined performance fin cold plates and chassis. We also offer friction stir welded performance-fin cold plates and chassis, flat tube cold plates, press lock copper tubed cold plates, vacuum brazed and CNC machined copper cold plates, stamped and vacuum brazed cold plates, custom channeled cold plates with ladder configuration, inner-finned brazed cold plates, and aluminum extruded and welded or brazed cold plates. Additionally, we have aluminum die-casting and welded or brazed cold plate options available.

▲ Stamped and vacuum brazed cold plate

Vacuum brazing is an advanced technique for joining materials that produces parts with robust, rust-resistant connections. This process involves using a filler metal that has a lower melting point than the main metal to fuse two aluminum plates together by utilizing capillary action. The advantages of vacuum brazing include even heating, precise temperature control, and the ability to achieve reusable results without the need for additional cleaning.

Most aluminum cold plates are joined using vacuum brazing, which involves attaching aluminum fins between the plates. Before brazing, it is essential to thoroughly clean the cold plate to ensure that the capillary action works effectively during the process. To maintain alignment during brazing, the components are securely held in brazing fixtures.

The vacuum brazing of a cold plate and heat exchanger typically occurs at temperatures around 1100°F (593°C) and a vacuum level of 5 to 6 Torr. The specific conditions may vary depending on the alloys used, the total mass being brazed, and the type of vacuum furnace employed. The furnace controller monitors the temperature and vacuum levels, following a predetermined recipe that advances to the next stage until the brazing cycle is finished.

When comparing vacuum furnace brazing to other methods of joining aluminum, it becomes evident that it offers several technical benefits. These advantages include the creation of strong joints that are free from defects and leaks, and are almost as strong as the parent metal. Vacuum furnace brazing also provides resistance to high temperatures of up to 350°F (176°C). Additionally, this technique consistently produces reproducible results with precise joining surfaces, ensuring uniform thermal conductivity. Another advantage is that the parts are extremely clean, as there is no corrosive flux residue due to the flux-free process used in vacuum brazing, unlike dip brazing. Furthermore, minimal distortion occurs during vacuum brazing due to the even heating and cooling process. For these reasons, vacuum brazing is the preferred method for manufacturing high-performance aluminum cold plates and heat exchangers.

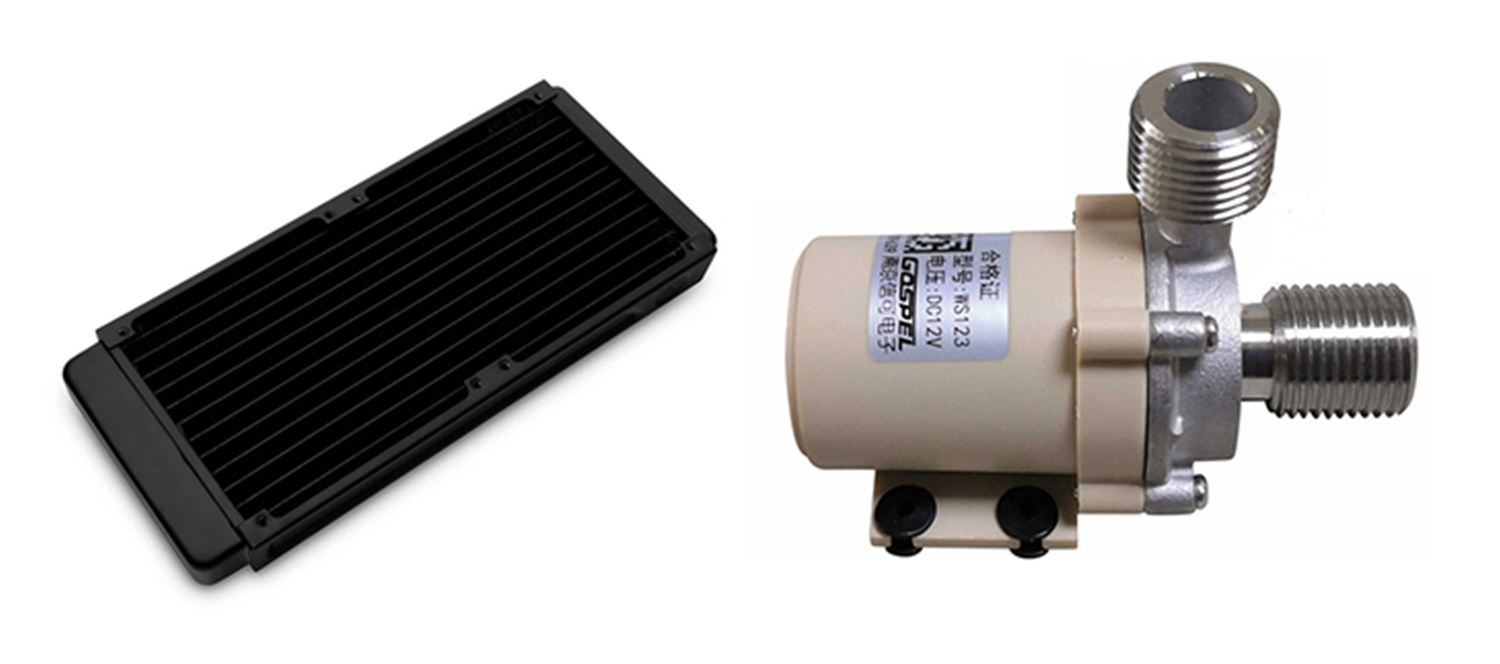

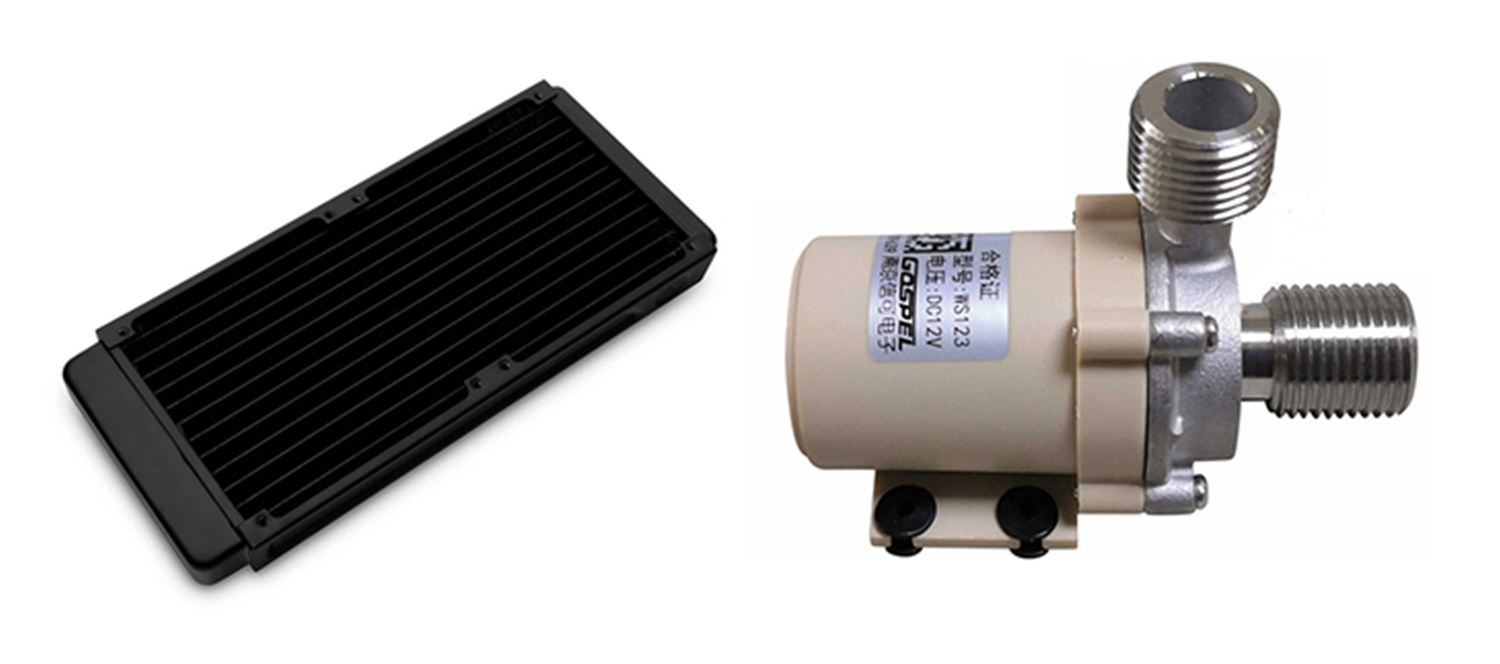

We also supply value added components as below

● Fittings and connectors

● Hoses and tubes

● Heat exchangers or radiators

● Pumps and reservoirs

● Fans

● Other accessories

▲ Radiator ▲ Pump

Product name : Cnc Machined custom Aluminium Cooling Block ev battery cooling liquid cold plate

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Aluminum alloy 3003, 6063,6061 |

2 | Dimension (L*W*T) | Up to 500*500*15 mm |

3 | Cooling Capacity | 500 to 1500 W |

4 | Working Pressure | 3 to 4 bars |

5 | Flatness | 0.15 mm |

6 | Surface roughness | 3.2 um |

7 | Flow rate | 5 to 10 L/min |

8 | Manufacturing Method | CNC machining Plus vacuum brazing |

9 | Joining Method | Vacuum Brazing |

10 | Cooling Method | Liquid cooling |

11 | Surface Finish | Mill finish or anodization |

12 | Coolant | Deionized Water,Inhibited Glycol and Water,Dielectric fluid |

13 | Warranty time | 1 year |

14 | Place of Region | Jiangsu province of China |

15 | Reference Standard | GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

Metalli provides a range of cold plate options, including vacuum brazed or controlled atmosphere brazed and CNC machined performance fin cold plates and chassis. We also offer friction stir welded performance-fin cold plates and chassis, flat tube cold plates, press lock copper tubed cold plates, vacuum brazed and CNC machined copper cold plates, stamped and vacuum brazed cold plates, custom channeled cold plates with ladder configuration, inner-finned brazed cold plates, and aluminum extruded and welded or brazed cold plates. Additionally, we have aluminum die-casting and welded or brazed cold plate options available.

▲ Stamped and vacuum brazed cold plate

Vacuum brazing is an advanced technique for joining materials that produces parts with robust, rust-resistant connections. This process involves using a filler metal that has a lower melting point than the main metal to fuse two aluminum plates together by utilizing capillary action. The advantages of vacuum brazing include even heating, precise temperature control, and the ability to achieve reusable results without the need for additional cleaning.

Most aluminum cold plates are joined using vacuum brazing, which involves attaching aluminum fins between the plates. Before brazing, it is essential to thoroughly clean the cold plate to ensure that the capillary action works effectively during the process. To maintain alignment during brazing, the components are securely held in brazing fixtures.

The vacuum brazing of a cold plate and heat exchanger typically occurs at temperatures around 1100°F (593°C) and a vacuum level of 5 to 6 Torr. The specific conditions may vary depending on the alloys used, the total mass being brazed, and the type of vacuum furnace employed. The furnace controller monitors the temperature and vacuum levels, following a predetermined recipe that advances to the next stage until the brazing cycle is finished.

When comparing vacuum furnace brazing to other methods of joining aluminum, it becomes evident that it offers several technical benefits. These advantages include the creation of strong joints that are free from defects and leaks, and are almost as strong as the parent metal. Vacuum furnace brazing also provides resistance to high temperatures of up to 350°F (176°C). Additionally, this technique consistently produces reproducible results with precise joining surfaces, ensuring uniform thermal conductivity. Another advantage is that the parts are extremely clean, as there is no corrosive flux residue due to the flux-free process used in vacuum brazing, unlike dip brazing. Furthermore, minimal distortion occurs during vacuum brazing due to the even heating and cooling process. For these reasons, vacuum brazing is the preferred method for manufacturing high-performance aluminum cold plates and heat exchangers.

We also supply value added components as below

● Fittings and connectors

● Hoses and tubes

● Heat exchangers or radiators

● Pumps and reservoirs

● Fans

● Other accessories

▲ Radiator ▲ Pump