- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

Product name : aluminum gpu liquid water cooling plate block

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Aluminum alloy 3003, 6063,6061 |

2 | Dimension (L*W*T) | Up to 500*500*15 mm |

3 | Cooling Capacity | 500 to 1500 W |

4 | Working Pressure | 3 to 4 bars |

5 | Flatness | 0.15 mm |

6 | Surface roughness | 3.2 um |

7 | Flow rate | 5 to 10 L/min |

8 | Manufacturing Method | CNC machining Plus vacuum brazing |

9 | Joining Method | Vacuum Brazing |

10 | Cooling Method | Liquid cooling |

11 | Surface Finish | Mill finish or anodization |

12 | Coolant | Deionized Water,Inhibited Glycol and Water,Dielectric fluid |

13 | Warranty time | 1 year |

14 | Place of Region | Jiangsu province of China |

15 | Reference Standard | GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

Metalli is a leading company that specializes in advanced cold plate technologies. Our product lineup consists of cutting-edge vacuum brazed or controlled atmosphere brazed and CNC machined performance fin cold plates and chassis, as well as friction stir welded (FSW) performance-fin cold plates and chassis. We also offer flat tube cold plates, press lock copper tubed cold plates, vacuum brazed and CNC machined copper cold plates, and stamped and vacuum brazed cold plates.

At Metalli, we take great pride in our commitment to innovation and excellence. Our aluminum die casting and welded or brazed cold plate exemplify our dedication to delivering top-notch products to our valued customers. With our wide array of cold plate technologies, we are confident that we can provide the ideal solution to cater to your specific requirements.

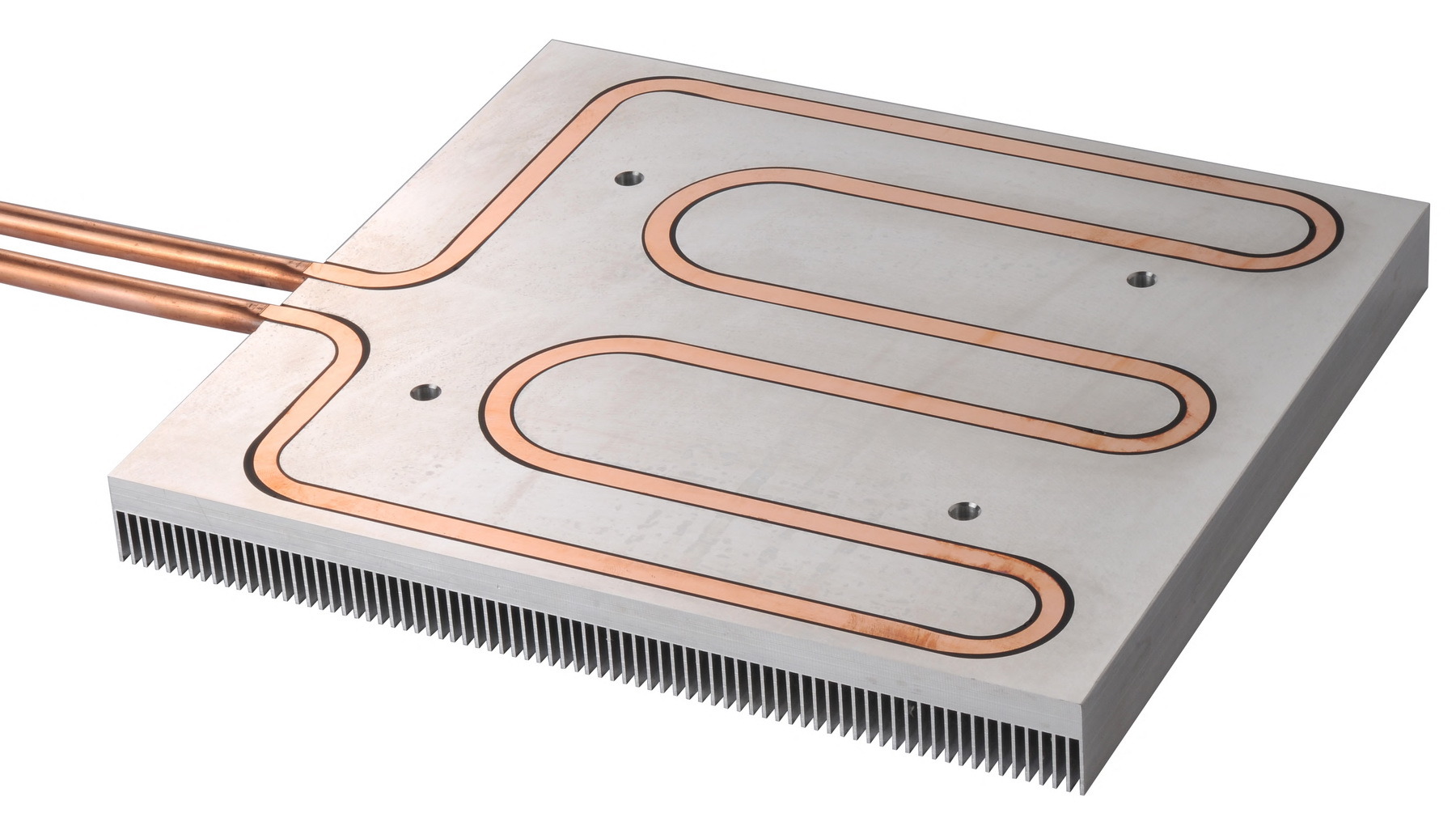

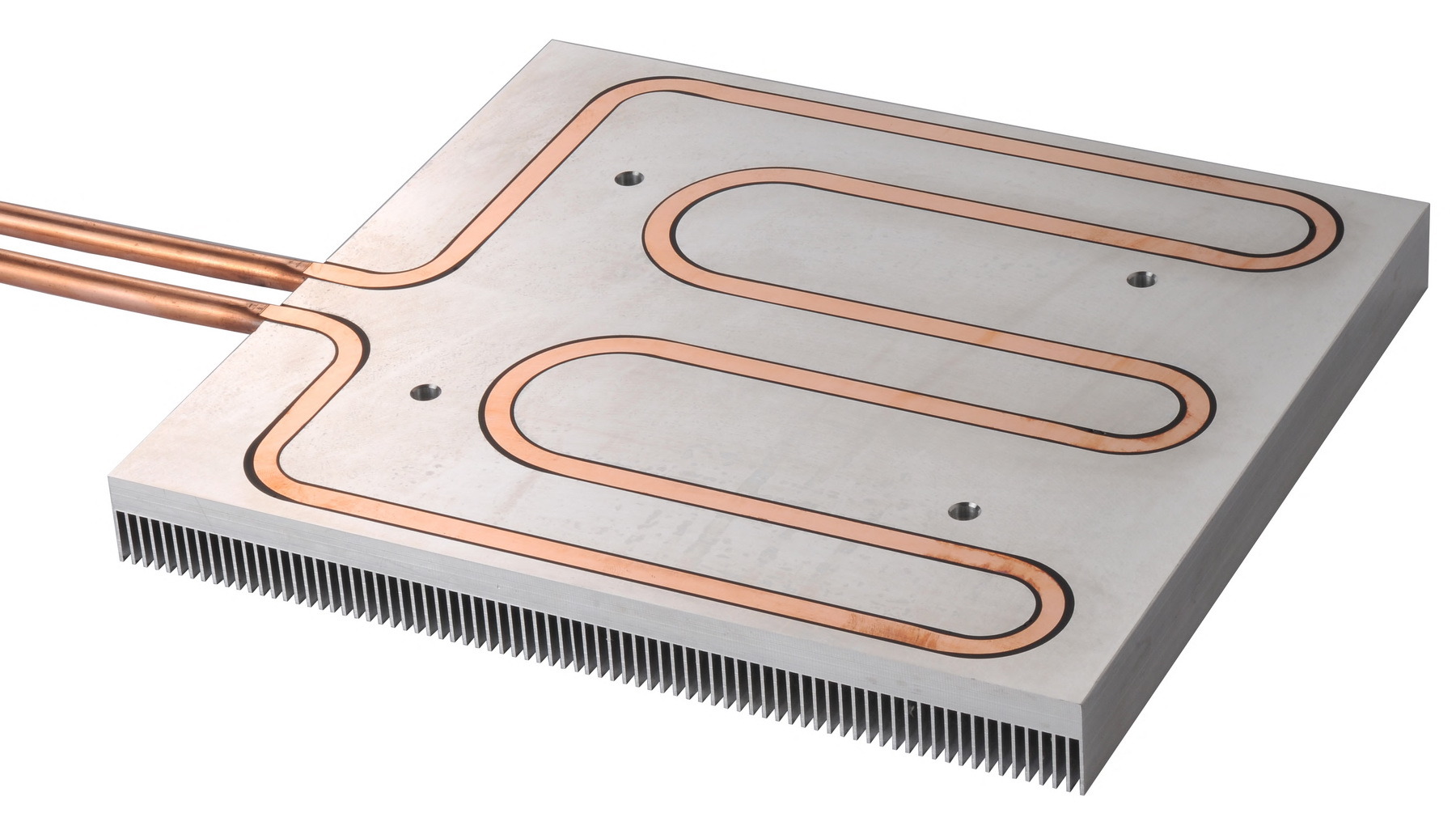

▲ Stamped and vacuum brazed cold plate ▲ Copper tubed cold plate

Liquid Cooling System Considerations

Allowable pressure drop, flow rate, and material compatibility should always be considered when choosing your cold plate and liquid system components. The allowable pressure drop is directly correlated with the pump and the force and flow rate at which it moves the fluid through the system. Materials and fluids need to be compatible through the entire system to prevent galvanic corrosion as well as optimizing your system for your application.

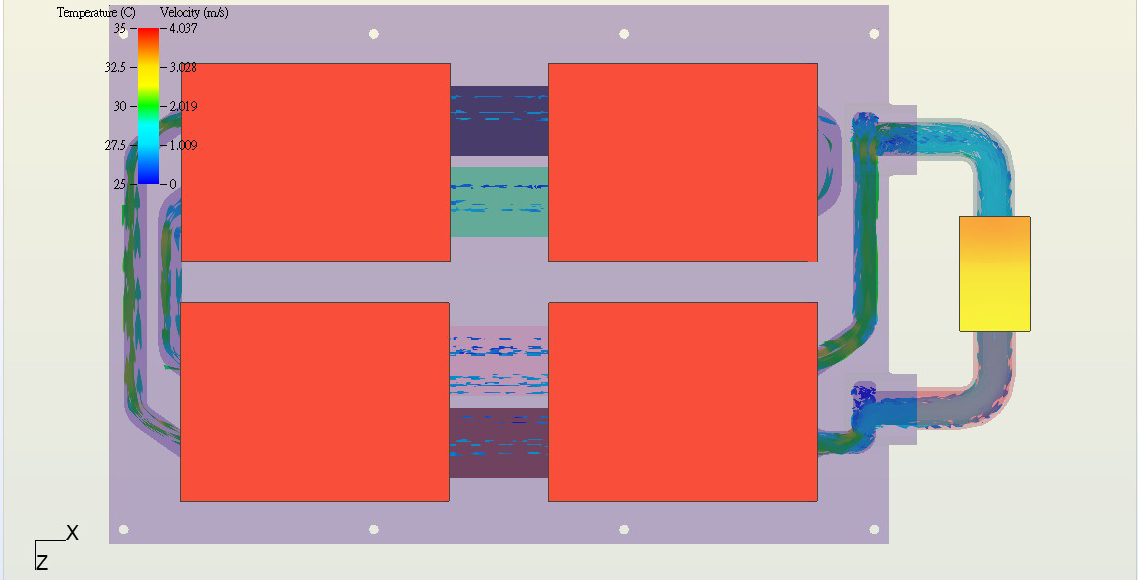

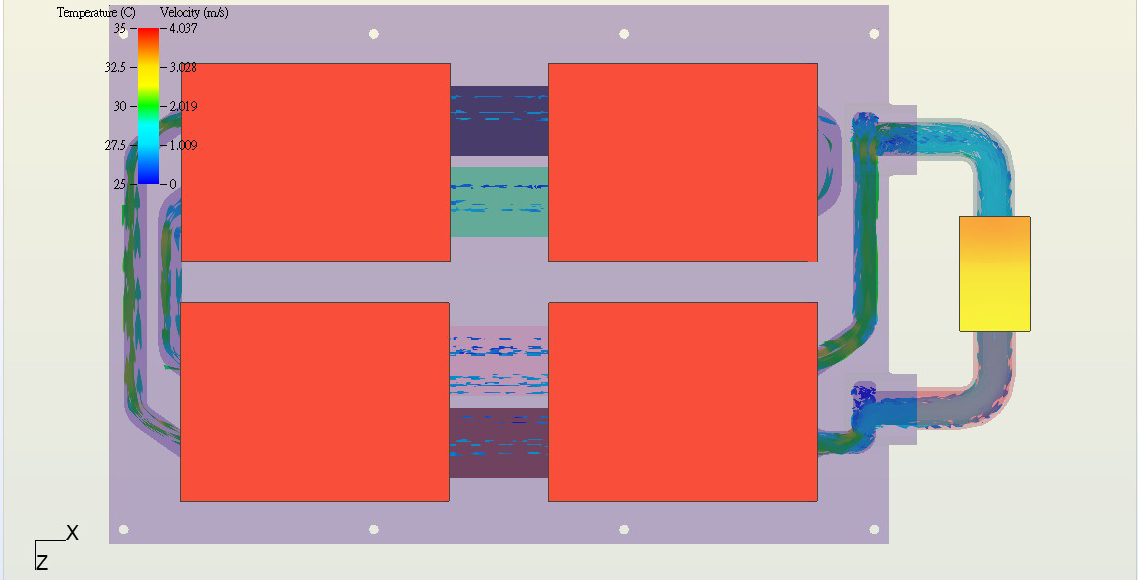

▲ Thermal simulation for cold plate

A fluid cooling system is a hydraulic setup that usually includes a chilled plate that connects with the heat source, a pump that moves the liquid throughout the system, and a device that releases the heat absorbed by the liquid.

The chilled plate can be as basic as a copper tube linked to an aluminum plate or they can be very intricate, using various methods to maximize heat transfer. These methods may involve advanced fins for enhanced heat transfer, specially designed tiny or medium-sized channels, or different manufacturing techniques like vacuum, CAB, or dip brazing.

Q: Are you trading company or manufacturer ?

A: We are manufacturer for the CNC machining ,extrusion ,skived fin process,soldering assembly ,brazing ,FSW process,vapor chamber and various hardware metal parts .

Q: Can you provide the sample for testing ?

A: Yes ,we can provide the the sample for testing .

Q: I do not have drawing, what can I do?

A: We can provide the customized design service for customer ,please kindly tell me your requirement .

Q: What documents will be offer along with the goods?

A: Documents will be offered based on your requirement, like dimension inspection report, delivery note, material certification, MSDS, COC and so on.

Q: What is your usual terms of payments?

A: it will be T/T ,Paypal ,Ali pay etc .

We also supply value added components as below

● Fittings and connectors

● Hoses and tubes

● Heat exchangers or radiators

● Pumps and reservoirs

● Fans

● Other accessories

Product name : aluminum gpu liquid water cooling plate block

PRODUCT DESCRIPTION | ||

NO. | ITEM | DESCRIPTION |

1 | Material | Aluminum alloy 3003, 6063,6061 |

2 | Dimension (L*W*T) | Up to 500*500*15 mm |

3 | Cooling Capacity | 500 to 1500 W |

4 | Working Pressure | 3 to 4 bars |

5 | Flatness | 0.15 mm |

6 | Surface roughness | 3.2 um |

7 | Flow rate | 5 to 10 L/min |

8 | Manufacturing Method | CNC machining Plus vacuum brazing |

9 | Joining Method | Vacuum Brazing |

10 | Cooling Method | Liquid cooling |

11 | Surface Finish | Mill finish or anodization |

12 | Coolant | Deionized Water,Inhibited Glycol and Water,Dielectric fluid |

13 | Warranty time | 1 year |

14 | Place of Region | Jiangsu province of China |

15 | Reference Standard | GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

Metalli is a leading company that specializes in advanced cold plate technologies. Our product lineup consists of cutting-edge vacuum brazed or controlled atmosphere brazed and CNC machined performance fin cold plates and chassis, as well as friction stir welded (FSW) performance-fin cold plates and chassis. We also offer flat tube cold plates, press lock copper tubed cold plates, vacuum brazed and CNC machined copper cold plates, and stamped and vacuum brazed cold plates.

At Metalli, we take great pride in our commitment to innovation and excellence. Our aluminum die casting and welded or brazed cold plate exemplify our dedication to delivering top-notch products to our valued customers. With our wide array of cold plate technologies, we are confident that we can provide the ideal solution to cater to your specific requirements.

▲ Stamped and vacuum brazed cold plate ▲ Copper tubed cold plate

Liquid Cooling System Considerations

Allowable pressure drop, flow rate, and material compatibility should always be considered when choosing your cold plate and liquid system components. The allowable pressure drop is directly correlated with the pump and the force and flow rate at which it moves the fluid through the system. Materials and fluids need to be compatible through the entire system to prevent galvanic corrosion as well as optimizing your system for your application.

▲ Thermal simulation for cold plate

A fluid cooling system is a hydraulic setup that usually includes a chilled plate that connects with the heat source, a pump that moves the liquid throughout the system, and a device that releases the heat absorbed by the liquid.

The chilled plate can be as basic as a copper tube linked to an aluminum plate or they can be very intricate, using various methods to maximize heat transfer. These methods may involve advanced fins for enhanced heat transfer, specially designed tiny or medium-sized channels, or different manufacturing techniques like vacuum, CAB, or dip brazing.

Q: Are you trading company or manufacturer ?

A: We are manufacturer for the CNC machining ,extrusion ,skived fin process,soldering assembly ,brazing ,FSW process,vapor chamber and various hardware metal parts .

Q: Can you provide the sample for testing ?

A: Yes ,we can provide the the sample for testing .

Q: I do not have drawing, what can I do?

A: We can provide the customized design service for customer ,please kindly tell me your requirement .

Q: What documents will be offer along with the goods?

A: Documents will be offered based on your requirement, like dimension inspection report, delivery note, material certification, MSDS, COC and so on.

Q: What is your usual terms of payments?

A: it will be T/T ,Paypal ,Ali pay etc .

We also supply value added components as below

● Fittings and connectors

● Hoses and tubes

● Heat exchangers or radiators

● Pumps and reservoirs

● Fans

● Other accessories